Carbon Nanotubes: Fundamentals, Properties and Industrial Applications (2025)

Carbon nanotubes are cylindrical nanostructures composed of carbon atoms arranged in a hexagonal lattice, which have used significant academic and industrial interest due to their unique physical, chemical, and mechanical properties.

Their exceptional mechanical strength, electrical conductivity, and thermal stability enable a range of innovative applications across fields such as electronics, composite materials, coatings, and biomedical devices. Initially discovered in the early 1990s and available in both single-walled (SWCNTs) and multi-walled (MWCNTs) forms, carbon nanotubes continue to play a pivotal role in advancing modern science and technology. This comprehensive overview examines their fundamental properties, diverse applications, and emerging trends, providing essential insights into the evolving impact of carbon nanotube technology.

What are Carbon Nanotubes?

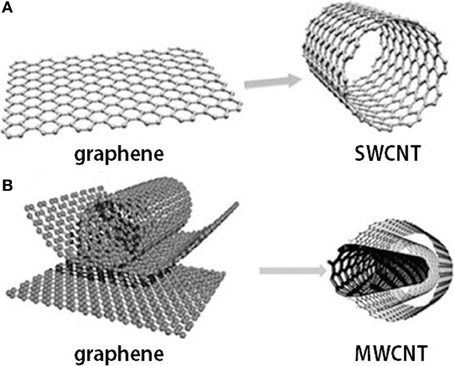

Carbon nanotubes are defined by their nanoscale diameters and high aspect ratios. Most commonly, SWCNTs are envisioned as graphene sheets rolled seamlessly into hollow cylinders along a specific vector from the two-dimensional hexagonal lattice. This structural formation creates a helical lattice of carbon atoms, which is stabilized by enforced periodic boundary conditions along the roll-up direction.

In contrast, MWCNTs consist of multiple concentric SWCNTs bonded together via van der Waals interactions. Their layered configuration is often compared to tree rings, with each nested tube contributing to the overall properties of the composite structure.

Key Properties of Carbon Nanotubes

Carbon nanotubes are referred to as tubes with less than 100 nanometers diameter and undetermined structure of carbon wall. Lukyanovich and Radushkevich discovered such tubes in 1952. Most of the studies are focused on the nanotubes of carbon, as compared to other compositions. That's why they are commonly referred to as MWNT, SWNT, and NT. When carbon nanotube is made from the general methods of production, the carbon nanotube's length is much larger as compared to its diameter, therefore, the carbon nanotubes length is assumed as infinite for various purposes.

While other nanotubes are semiconductors, the carbon ones display excellent electrical conductivity. Their thermal conductivity and tensile strength are exceptional due to the bond-strength between the atoms of carbon and their nanostructure. Also, they are chemically modifiable. In many technological areas like nanotechnology, composite materials, optics, electronics, and other materials science applications, these characteristics are very useful and beneficial.

Along the tube axis, all these tubes have helical and translational symmetry too and possess nontrivial rotational symmetry. Also, most of them are chiral, therefore the tube and mirror image of the tube isn’t capable of being superimposed. A pair of integers labels the single-wall carbon nanotubes as the construction allows. Some of the specific single-wall carbon nanotubes are metallic whereas others are either moderate or small bandgap semiconductors. The rolling of hexagonal lattice whether it is from front to back or back to front doesn't determine their electrical characteristics. Also, such characteristics don't depend on the tube and its mirror image.

Various single-walled carbon nanotube's characteristics majorly depend on the (n,m) type. It is non-monotonic dependence. The bandgap specifically, can range from 0 to almost 2 eV and semiconducting or metallic behavior can be displayed by the electrical conductivity.

Figure 1: Graphene and carbon nanotubes as (A) single wall carbon nanotube (SWCNT) and (B) multi-wall carbon nanotube (MWCNT) structures.

Mechanical Properties

Carbon nanotubes exhibit extraordinary mechanical strength due to the strong covalent sp² bonds between carbon atoms.

- High Tensile Strength: MWCNTs have demonstrated tensile strengths up to 63 gigapascals, with some individual CNT shells reaching 100 gigapascals.

- High Specific Strength: With a specific strength vastly surpassing that of high-carbon steel, CNTs are ideal for reinforcing advanced composite materials.

- Buckling Behavior: Their high aspect ratio and hollow structure can lead to buckling under bending or torsional stress, although techniques such as high-energy electron irradiation have enhanced inter-tube bonding and overall strength.

Electrical Properties

CNTs display diverse electrical behaviors that depend on their structure:

- Conductivity: While some single-walled CNTs are metallic, others behave as semiconductors with bandgaps ranging from 0 to nearly 2 eV.

- High Current Density: Metallic CNTs can carry electric currents up to 1000 times higher than conventional copper interconnects, making them attractive for next-generation electronics and interconnect applications.

Optical Properties

CNTs are also characterized by unique optical responses:

- Spectroscopic Identification: Techniques such as Raman spectroscopy, photoluminescence, and optical absorption are routinely used for rapid, non-destructive CNT characterization, facilitating quality control in industrial production.

- Application in Sensors: These optical properties further enhance the utility of CNTs in sensor and photonic applications.

Thermal Properties

The thermal conductivity of carbon nanotubes is exceptional along the tube axis due to ballistic phonon transport:

- High Axial Conductivity: Individual SWCNTs can exhibit thermal conductivities around 3500 W/m·K.

- Insulating Lateral Behavior: Perpendicular to the axis, CNTs behave as effective insulators.

- Temperature Stability: Their performance remains robust under various environmental conditions, with stability reaching up to 2800°C in a vacuum.

Industrial Applications of Carbon Nanotubes

There are many ways in which carbon nanotubes can be utilized in the industry however the best ones are explained further. It is due to their remarkable performance in every industry that their consumption is now increasing quite rapidly.

Composite Materials and Structural Reinforcement

Carbon nanotubes (CNTs) are extensively used to enhance the performance of composite materials. Their high strength-to-weight ratio and exceptional stiffness make them ideal for:

- Load-Bearing Components: Incorporation into precursor resins and polymers results in composites with improved toughness, strength, and impact resistance. This is especially beneficial in aerospace, automotive, and sporting goods industries.

- Fiber Reinforcement: CNTs are integrated into carbon fiber and glass fiber composites, significantly enhancing mechanical performance. This application is critical for developing lightweight, high-strength materials for aircraft, wind turbines, and advanced structural components.

Electronics and Energy Applications

The superior electrical and thermal properties of CNTs have paved the way for innovative solutions in electronics and energy systems:

- Interconnects and Conductors: CNTs can replace traditional copper wiring in microelectronics. Their ability to carry high current densities, up to 1000 times that of copper, makes them promising for next-generation integrated circuits and flexible electronics.

- Field-Effect Transistors (CNTFETs): CNT-based transistors leverage the unique electronic characteristics of single-walled CNTs to achieve low-power, high-speed digital switching, potentially transforming the semiconductor industry.

- Energy Storage Devices: CNTs are utilized in batteries and supercapacitors to enhance conductivity and improve charge/discharge cycles. Their inclusion in electrode materials results in energy storage systems with higher performance, longer life, and faster charging capabilities.

- Thermal Management Solutions: Due to their high thermal conductivity, CNTs are employed in heat sinks and thermal interface materials. These components are vital for cooling high-performance electronics, LED lighting systems, and power devices.

Coatings, Films, and Surface Functionalization

CNTs offer unique advantages when used as additives in coatings and thin films:

- Anti-Corrosion and Protective Coatings: CNT-enhanced paints provide improved durability and resistance to corrosion. These coatings are used in marine, automotive, and industrial applications to extend the lifespan of metal structures.

- Electromagnetic Interference (EMI) Shielding: CNT composites offer effective EMI shielding, protecting sensitive electronics from interference. This is essential in consumer electronics, aerospace, and defense sectors.

- Transparent Conductive Films: CNT-based films serve as flexible, transparent conductors, offering an alternative to brittle materials like indium tin oxide (ITO) in touchscreens, displays, and solar cells.

- Smart Coatings: By incorporating CNTs into coatings, manufacturers can develop surfaces with self-cleaning, anti-fouling, or even self-healing properties, ideal for architectural, automotive, and biomedical applications.

Biomedical and Healthcare Innovations

CNTs are rapidly emerging as key components in the biomedical field due to their biocompatibility and functional versatility:

- Drug Delivery Systems: Functionalized CNTs can serve as vehicles for targeted drug delivery, enabling precise treatment of diseases with minimal side effects.

- Biosensors: Their high surface area and unique electronic properties are harnessed in biosensors for detecting biomarkers, pathogens, and environmental toxins. CNT-based sensors offer high sensitivity and rapid response times.

- Tissue Engineering: CNTs are integrated into scaffolds and composite materials to support tissue regeneration and repair. Their mechanical properties help mimic the natural extracellular matrix, promoting cell growth and differentiation.

- Medical Imaging and Diagnostics: Advances in CNT research have led to improved imaging contrast agents and diagnostic tools, enhancing the capabilities of non-invasive medical imaging techniques.

Environmental and Energy Efficiency Applications

The versatility of CNTs extends to environmental and energy-efficient solutions:

- Water Purification and Filtration: CNT-based membranes and filters exhibit high permeability and selectivity, making them effective for removing contaminants from water.

- Air Quality Improvement: CNTs are being explored for their potential in air filtration systems, capturing pollutants and particulates to improve indoor and outdoor air quality.

- Catalysis and Sensor Technologies: CNTs serve as supports or active components in catalytic processes, contributing to cleaner energy production and environmental remediation. They are also integrated into sensors for monitoring environmental conditions in real time.

Emerging Applications

As research continues to advance, carbon nanotubes are finding new roles in diverse sectors:

- Smart Textiles and Wearable Electronics: CNTs are being incorporated into fabrics to create smart textiles with embedded sensors for health monitoring, energy harvesting, and enhanced durability. These textiles offer promising applications in military, sports, and healthcare.

- Optoelectronic Devices: The optical properties of CNTs are exploited in developing photodetectors, light-emitting diodes (LEDs), and solar cells. Their ability to interact with light makes them ideal for next-generation optoelectronic devices.

- Flexible and Stretchable Electronics: The inherent flexibility and high conductivity of CNTs make them excellent candidates for developing wearable, foldable, or stretchable electronic devices, providing new opportunities for innovation in consumer electronics and robotics.

Conclusion

In conclusion, Carbon nanotubes are thin elastic tubes made up of carbon and the reason that they are called nano is that the diameter of these tubes is very small and is measured in the nanoscale. They are an essential part of the industry and are highly used in the industry as they are capable of offering a lot of benefits and ease to the consumers and the industries that they are a part of. They have exceptional properties such as mechanical, electrical, optical, and thermal properties. All these properties are so strong that they are credited throughout the world in different industries.

Carbon nanotubes are revolutionizing multiple industries with their unmatched properties. At Nanografi, our innovative CNT-based solutions empower advanced composites, energy devices, and high-performance coatings—driving next-generation products and breakthroughs in material science.

To get more information, you can visit Blografi.

References

IntechOpen. (n.d.). Carbon nanotube industrial applications. Retrieved from https://www.intechopen.com/books/carbon-nanotubes-applications-on-electron-devices/carbon-nanotube-industrial-applications

Azonano. (n.d.). Applications of carbon nanotubes. Retrieved from https://www.azonano.com/article.aspx?ArticleID=4842

ResearchGate. (n.d.). Potential applications of carbon nanotubes. Retrieved from https://www.researchgate.net/publication/225938971_Potential_Applications_of_Carbon_Nanotubes

Prescouter. (2017, March). Applications of carbon nanotubes. Retrieved from https://www.prescouter.com/2017/03/applications-carbon-nanotubes/

Hindawi. (2013). Potential applications of carbon nanotubes. Journal of Chemistry, 2013, Article 676815. Retrieved from https://www.hindawi.com/journals/jchem/2013/676815/

Nanostructures: A Platform for Brain Repair and Augmentation - Scientific Figure on ResearchGate. Available from: https://www.researchgate.net/figure/Graphene-and-carbon-nanotubes-as-A-single-wall-carbon-nanotube-SWCNT-and-B_fig1_263740854 [accessed 24 Mar 2025]

Recent Posts

-

Key Performance Metrics in Nanomaterials: How Performance Is Actually Evaluated

Introduction When nanomaterials are discussed, performance is often reduced isolated peak performanc …29th Jan 2026 -

Why Not All Graphene Is the Same: Structural Differences That Define Performance

Introduction Graphene is one of the most widely discussed materials in advanced technology, yet its …23rd Jan 2026 -

What Are Advanced Materials and Why They Matter for High-Tech Industries

Introduction Advanced materials are no longer peripheral inputs in technology development; they have …9th Jan 2026