Zirconia Yttria Nanopowder

Zirconia yttria nanopowders are valuable ceramic materials with interesting properties such as high ionic conductivity, thermal resistivity, chemical stability, and mechanical strength.

These properties of zirconia yttria nanopowders are used in dental restorations, solid oxide fuel cells, catalytic applications, sensors, and temperature resistant coatings. Get to know Nanografi, which specializes in the production and supply of various advanced materials, including zirconia yttria nanopowders.

Introduction

Comprising zirconium dioxide (ZrO₂) stabilized with yttrium oxide (Y₂O₃), this nanopowder exhibits remarkable strength, toughness, and resistance to wear and corrosion. Its unique properties make it ideal for various high-performance applications, including dental and orthopedic implants, thermal barrier coatings, and fuel cells. The nanoscale particles enhance the material's surface area and reactivity, offering significant advantages in both industrial and biomedical fields.

What is Zirconia Yttria?

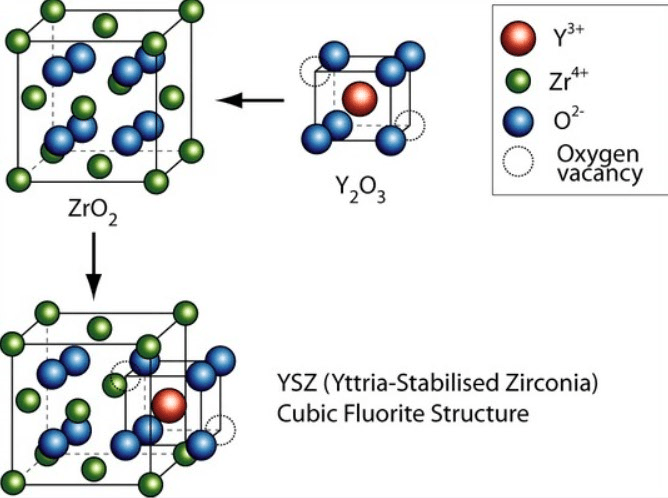

Zirconia (ZrO2) is a well-known compound used in various different applications such as oxygen sensors, and fuel cell membranes due to the high O2 diffusivity; structural and biomedical applications due to its high strength and toughness. ZrO2 is found in two different crystallographic structures; monoclinic to tetragonal at room temperature and tetragonal to cubic at high temperatures (2370°C). The high-temperature cubic phase is very important due to its desirable properties such as high ionic conductivity and mechanical strength comparedto tetragonal and monoclinic configurations. However, cubic ZrO2 is unstable in bulk forms at ambient temperature. Pure cubic zirconia undergoes volume changes and possible mechanical stresses or failures originated from the phase transitions during heating or cooling. For this reason, it is a common practice to dope pure zirconia with rare earth oxides such as yttria (Y2O3), magnesia, calcium oxide, or rare earth oxides. Doping is achieved through the substitution of zirconia cation with the rare earth oxide molecule.

Figure 1. Illustration of the yttria-stabilized zirconia structure.

Properties of Yttria Stabilized Zirconia

Zirconia yttria is known as the stabilized form of cubic zirconia with the doping of yttria into its structure. This configuration is also referred to as yttria-stabilized zirconia (YSZ). The unique properties of YSZ have attracted a lot of attention. YSZ maintains its cubic structure between room temperature and 2700°C, present excellent chemical stability, low thermal conductivity, and high oxygen ionic conductivity. The low thermal conductivity of YSZ at high temperatures preserves the desired cubic shape of the YSZ structure. Fully stabilized zirconia (FSZ) requires 8% doping of yttria to maintain its cubic shape at room temperatures. In addition to fully stabilized zirconia, partially stabilized zirconia (Y-PSZ) has also been a topic of studies with less than 8% yttria doping. Partially stabilized zirconia exhibits excellent strength and fracture toughness due to the stress-induced martensitic transformation of tetragonal to monoclinic symmetry. On the other hand, fully stabilized zirconia offers excellent stability at high temperatures.

YZS nanopowders exhibit superior properties to the bulk powders due to their high specific surface area, massive interfaces, and grain boundaries. Several different approaches to the fabrication of yttria zirconia nanopowders have been studied to obtain higher specific surface areas and stability.

Figure 2. Some product features of Nanografi's Zirconia-Yttria nanopowder.

Synthesis Methods of Zirconia Yttria

The synthesis of high-quality YSZ nanopowders requires the disposing of powdered precursors with high purity, nanometer-sized primary particles, narrow sizes distribution, and weakly bonded primary particles. The commonly used approaches are; hydrothermal methods, homogeneous precipitation, sol-gel method, plasma spray synthesis, reverse micro-emulsion route, and combustion synthesis apart from the conventional solid-state reaction. For all these synthesis methods, the preparation condition plays a crucial role in the properties of the powders and each method has its own advantages as well as disadvantages.

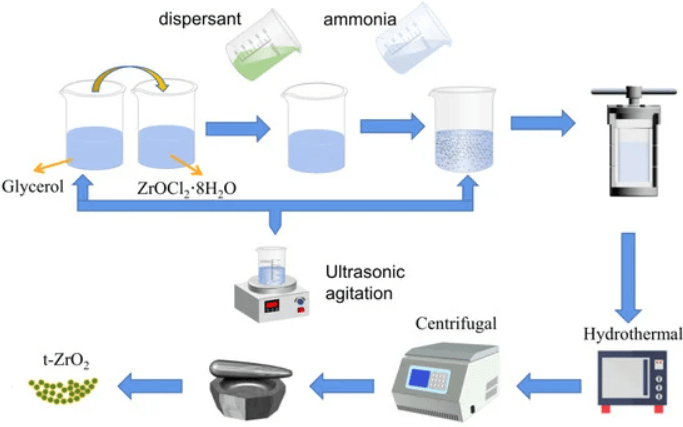

The hydrothermal synthesis method is an inexpensive simple method to obtain YSZ nanopowders. This method involves an initial co-precipitation, and the formed precipitate needs to be heat-treated at high temperatures to obtain crystallinity. Microwave assistance is usually combined with hydrothermal methods to obtain high temperatures up to 800°C. In the co-precipitation method, precipitation of yttria and zirconia is observed in a single solution medium. The process conditions such as the addition of the precipitating agent, sequence of addition, rate of addition, etc. have to be optimized to get powders of the required quality.

Figure 3. An example of the preparation of tetragonal phase nano-zirconia by hydrothermal method.

Plasma spray techniques offer shorter and controllable reaction times, many parameters such as feeding rate, plasma power, the composition of the plasma gas, solvents, and precursors, and size of the atomization nozzle. Another downside to the plasma spray techniques is the high cost.

In the reverse microemulsion method, the parameters such as the molar ratio of water to surfactant, the type of ions, electrolyte concentration in the aqueous phase, and the choice of co-surfactant affect the size and shape of reverse micelles. The conventional solid-state reaction usually leads to a coarser inhomogeneous product, which requires high-temperature sintering.

Combustion synthesis is an attractive method for the preparation of crystalline, homogeneous YZS nanopowders with high purity and a narrow particle size distribution. In this method, the time required for achieving high temperatures is significantly shot due to exothermic reactions. Microwave assistant heating control can also be utilized in this method yielding cubic particles with approximately 15 nm sizes.

The sol-gel method is another important synthesis method for YSZ nanoparticles. This method builds up particles molecule-by-molecule. It is flexible, low-cost, does not require aggressive solutions, and has relatively simple reaction conditions. Zirconium and yttrium salts are often chosen as precursors, and sometimes chemicals with large molecular weights are used as dispersants. Particle size can be controlled through different sintering temperatures. For example, according to C. Suciu et al., sintering at 500°C results in 6-7 nm particle size, while sintering at 1000°C results in 26-33 nm.

As it is demonstrated above, there are various different routes for the synthesis of zirconia yttria nanopowders. In fact, the examples above ave other different variations further increasing the possible routes for YSZ production. On top of that, it is possible to tailor the properties of zirconia yttria powders in accordance with the necessities of different application areas.

Applications of Yttria Stabilized Zirconia

Zirconia yttria nanopowders are renowned for their exceptional properties, including thermal resistivity, chemical stability, high ionic conductivity, and mechanical strength. These attributes make them highly valuable across a variety of applications, ranging from dental bioceramics to thermal barrier coatings, gas sensors, catalysts, and solid oxide fuel cells (SOFCs).

Dental Bioceramics

Partially stabilized tetragonal zirconia yttria nanopowders are ideal for ceramic dental restorations due to their:

- Excellent mechanical properties

- Optimal biocompatibility

- High chemical stability

To mimic the optical behavior of natural teeth, which appear whiter under sunlight due to blue fluorescence under UV light, zirconia yttria dental restorations often require optical adjustments. This is typically achieved by doping the material with fluorescent substances like Eu2+ to match the translucency and natural fluorescence of human teeth.

Solid Oxide Fuel Cells (SOFCs)

Zirconia yttria nanopowders' high ionic conductivity, which facilitates O2- movement, is crucial in SOFC applications. Composites of yttria-stabilized zirconia (YSZ) with nickel are used as anodes, while YSZ serves as the electrolyte between electrodes.

Key points include:

- Reduction of Operating Temperatures: YSZ helps lower the high operating temperatures of SOFCs from above 800°C to a range of 300-500°C.

- Optimal Dopant Concentration: Maximum ionic conductivity is achieved with an 8 mol% concentration of Y2O3.

- Nanocrystalline Structure: Nanoscale 8% YSZ powders, with crystal sizes of 5-10 nm, exhibit high surface areas (3-100 m²/g), making them effective electrolyte materials.

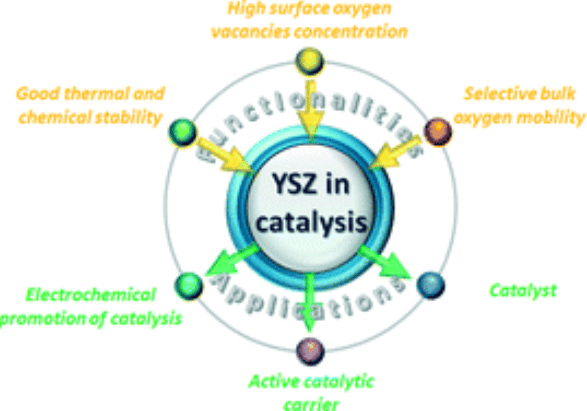

Catalytic Applications

Zirconia yttria nanopowders are used in catalytic applications due to their chemical stability and high ionic conductivity. They serve in various roles, such as electrolytic supports, catalytic supports, and catalysts in different reactions.

Notable uses include:

- Electrochemical Promotion of Catalysis: Utilizing the O2- conducting nature to control the activity and selectivity of electrochemical catalysts.

- Catalyst Support: Enhancing active surface areas and dispersion.

- Active Catalytic Support: Used in the oxidation of ethylene, toluene, and carbon monoxide.

- NOx Reduction: Combined with platinum and rhodium on a silicone support for effective NOx storage-reduction.

- Methane and Hydrocarbon Oxidation: Catalyzing total and partial oxidation of methane, hydrocarbons, and hydrogenation of CO and CO2.

Figure 4. Benefits of yttria stabilized zirconia (YSZ) in catalysis.

Sensor Applications

The high ionic conductivity of zirconia yttria nanopowders is also beneficial in oxygen and humidity sensors. These applications require materials with high density and specific surface areas.

Thermal Barrier Coatings

The low thermal conductivity of zirconia yttria nanopowders is utilized in temperature-resistant ceramic coatings, making them suitable for thermal barrier applications. By leveraging these properties, zirconia yttria nanopowders find diverse and critical applications in various industries, showcasing their versatility and importance.

Conclusion

Yttria is widely used as a dopant in zirconia structure in order to enhance the promising features of the zirconia nanopowders. Zirconia yttria nanopowders are well-known for their high O2- ionic conductivity, thermal resistivity, chemical stability, and mechanical strength. Several different synthesis routes that have previously used for metal oxide compounds have also been utilized for zirconia yttria nanopowder synthesis. Through the manipulation of synthesis parameters, it is possible to adjust the properties of YSZ nanopowders. The most commonly used synthesis methods are hydrothermal synthesis, homogeneous precipitation, sol-gel method, plasma spray synthesis, reverse micro-emulsion route, combustion synthesis, and solid-state reaction. Each of these synthesis methods holds different advantages and disadvantages. The resulting zirconia yttria nanopowders are exploited in various different applications. The mechanical properties and chemical stability of YSZ nanopowders are utilized in ceramic dental restorations. The ionic conductivity of YSZ nanopowder is extremely useful as catalyst supports and as catalysts in oxidation reactions of organic molecules as well as electrode or electrolyte materials in solid oxide fuel cells. Zirconia yttria nanopowders are also used in oxygen and humidity sensors as well as temperature resistant coatings.

To follow the latest developments and innovations related to nanotechnology, visit Blografi.

References

Hao, S. J., Wang, C., Liu, T. L., Mao, Z. M., Mao, Z. Q., & Wang, J. L. (2017). Fabrication of nanoscale yttria-stabilized zirconia for solid oxide fuel cell. International Journal of Hydrogen Energy, 42(50), 29949-29959.

Kuo, C. W., Shen, Y. H., Hung, I. M., Wen, S. B., Lee, H. E., & Wang, M. C. (2009). Effect of Y2O3 addition on the crystal growth and sintering behavior of YSZ nanopowders prepared by a sol–gel process. Journal of alloys and compounds, 472(1-2), 186-193.

Liu, S., Wang, J., Chen, Y., Song, Z., Han, B., Wu, H., Zhang, T., & Liu, M. (2023). Tetragonal Nanosized Zirconia: Hydrothermal Synthesis and Its Performance as a Promising Ceramic Reinforcement. Inorganics, 11(5), 217. https://doi.org/10.3390/INORGANICS11050217/S1

Prakasam, M., Valsan, S., Lu, Y., Balima, F., Lu, W., Piticescu, R., & Largeteau, A. (2018). Nanostructured pure and doped zirconia: synthesis and sintering for SOFC and optical applications. Sintering Technology: Method and Application, 85.

Shi, L., Zhao, F., Zhou, X., Chen, W., & Li, Y. (2014). Novel Eu2+-doped 3Y-TZP bioceramics with fluorescence similar to natural teeth. Ceramics International, 40(8), 13729-13733.

Tsampas, M. N., Sapountzi, F. M., & Vernoux, P. (2015). Applications of yttria stabilized zirconia (YSZ) in catalysis. Catalysis Science & Technology, 5(11), 4884-4900.

Yttria-stabilized zirconia - Wikipedia. (n.d.). Retrieved June 3, 2024, from https://en.wikipedia.org/wiki/Yttria-stabilized_zirconia

Recent Posts

-

Key Performance Metrics in Nanomaterials: How Performance Is Actually Evaluated

Introduction When nanomaterials are discussed, performance is often reduced isolated peak performanc …29th Jan 2026 -

Why Not All Graphene Is the Same: Structural Differences That Define Performance

Introduction Graphene is one of the most widely discussed materials in advanced technology, yet its …23rd Jan 2026 -

What Are Advanced Materials and Why They Matter for High-Tech Industries

Introduction Advanced materials are no longer peripheral inputs in technology development; they have …9th Jan 2026