Beyond Reduced Graphene Oxide: Discover Nanografi’s Advanced rGO-TEPA

As research in advanced materials expands, graphene derivatives with engineered surface chemistry are increasingly shaping next-generation technologies (Zhang et al., 2022; Grand View Research, 2024).

Among these, tetraethylene pentamine-functionalized reduced graphene oxide (rGO-TEPA) stands out for its ability to To combine high electrical conductivity with abundant amine functional groups that enable strong chemical interactions. Recent studies confirm that functionalized graphene derivatives are central to the development of advanced composites, energy systems, and environmental solutions. (Zhang et al., 2022; Grand View Research, 2024).

By grafting amine chains onto the graphene lattice, rGO-TEPA achieves enhanced interfacial bonding and improved dispersibility, two properties that conventional reduced graphene oxide (rGO) often lacks. Responding to the growing industrial need for consistent quality and supply, Nanografi now manufactures and provides high-purity rGO-TEPA, bridging the gap between laboratory innovation and commercial-scale production.

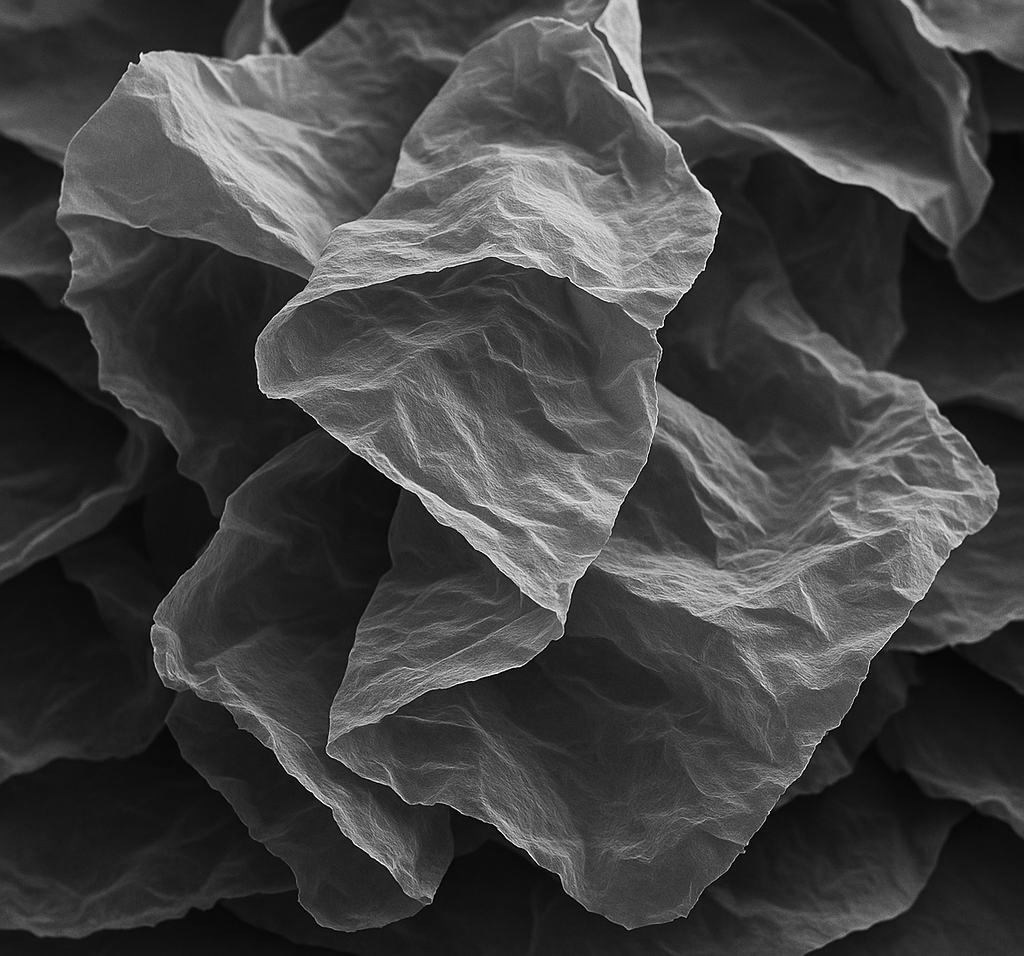

From Reduced Graphene Oxide to rGO-TEPA: Evolving Surface Chemistry

Graphene oxide (GO) contains abundant oxygen functionalities -hydroxyl, epoxy, and carboxyl groups- that render it hydrophilic but simultaneously disrupt the sp² carbon lattice. Reduction of GO restores electrical conductivity; however, it significantly decreases the number of reactive sites available for chemical bonding

Functionalization with tetraethylene pentamine (TEPA) addresses both limitations. The amine chains grafted onto the rGO surface not only assist in removing residual oxygenated groups but also introduce –NH₂ functionalities capable of forming covalent and hydrogen bonds. Alkhouzaam et al. (2022) demonstrated that TEPA treatment increased the C/O ratio by roughly 60 %, confirming substantial reduction and amination. This balance of conductivity and reactivity is what makes rGO-TEPA adaptable across industries.

The Science Behind Its Versatility

The performance of rGO-TEPA lies in its structural duality. The amine-terminated carbon sheets preserve the restored sp² conjugation for high electron mobility, while simultaneously enabling strong chemical interactions with metals, polymers, and ionic species. This unique combination makes the material valuable in three core engineering domains:

- Interfacial Engineering: Surface amine groups improve adhesion between rGO and host matrices, promoting stress transfer and Minimize particle aggregation

- Electron and Ion Transport: Reduced oxygen content restoreconductivity, while the nitrogen dopants Act as electron donors, accelerating charge transger kinetics in electrochemical systems.

- Surface Activity: Nitrogen atoms act as Lewis bases, enabling adsorption of heavy‑metal ions, immobilization of catalytic nanoparticles, and conjugation of biomolecules through coordination or hydrogen bonding.

These properties elevate rGO‑TEPA from an inert filler to an active functional component in advanced composites, energy devices, and environmental systems.

Applications Across Key Sectors

1. Energy and Electronics

Energy devices require materials with high electrical conductivity and long-term electrochemical stability across thousands of charge–discharge cycles. rGO-TEPA meets both needs. In batteries and supercapacitors, its compatibility with polymer matrices further enables applications in flexible and wearable electronics, where mechanical durability must coexist with efficient charge transport. In practice, TEPA‑modified rGO consistently demonstrates higher capacitance and superior cycle retention compared to unmodified rGO, offering a scalable pathway toward lightweight, long‑lasting power solutions.

2. Advanced Composites and Coatings

The amine-rich surface of rGO-TEPA promotes strong interfacial bonding with resin systems such as epoxy, polyurethane, or polyester. Even at low loadings, it improves tensile strength, elastic modulus, and impact toughness by facilitating efficient stress transfer across the filler–matrix interface.

In aerospace, automotive, and construction industries, this translates to lighter, Lighter yet stronger structures with improved electrical conductivity and thermal diffusivity.

Additionally, rGO-TEPA serves as a conductive additive in antistatic coatings, corrosion-resistant layers, and thermal-management surfaces, delivering multifunctional performance in a single formulation.

3. Environmental Remediation

Water purification remains one of the most urgent technological challenges, and amine-functionalized graphene derivatives are key tools in this domain. The amine groups of rGO-TEPA exhibit high bending affinity toward heavy-metal ions such as Pb(II), Cr(VI), and Cu(II).

Han et al. (2015) demonstrated that TEPA‑modified graphene foams achieved over 95% removal of Pb(II) ions under mild aqueous conditions, highlighting their exceptional adsorption capacity. Similarly, Rahdar (2025) emphasized the potential of amine‑functionalized GO materials for selective pollutant capture and regeneration cycles, confirming their suitability for sustainable water treatment.

These findings position rGO‑TEPA as a promising material for scalable filtration, wastewater remediation, and catalytic degradation systems, where both efficiency and reusability are critical.

4. Sensors and Smart Materials

In chemical and biosensing, surface functionality dictates both sensitivity and selectivity. The amine-decorated surface of rGO-TEPA interacts with analytes through electrostatic interactions, hydrogen bonding, and covalent conjugation, while its restored sp² network ensures low‑resistance electron pathways for rapid signal transmission.

Researchers have shown that functionalized graphene materials enhance the detection of gases, biomolecules, and ionic species due to these synergistic effects (Văduva et al., 2023).

Such characteristics position rGO-TEPA as a core material for next-generation sensors, environmental monitors, and smart surfaces embedded in industrial systems.

5. Emerging Frontiers

Beyond current industrial uses, rGO-TEPA is expanding into new domains such as catalysis, additive manufacturing, and biomedical engineering.

In catalysis, the amine the surface amine groups act as coordination sites for nanoparticle immobilization, improving dispersion stability, preventing agglomeration, and enhancing catalytic activity.

In additive manufacturing, rGO‑TEPA incorporation into polymer matrices enhances electrical conductivity, tensile strength, and interlayer adhesion of 3D‑printed filaments, enabling multifunctional printed components.

Meanwhile, in biomedicine, researchers are investigating its potential in drug delivery and bio scaffolds, leveraging its biocompatible amine chemistry—though further safety evaluations remain essential before large-scale adoption.

Expanding Market and Industrial Accessibility

The adoption of functionalized graphene materials is accelerating globally, driven by their proven impact across multiple verticals. Market data forecasts an annual growth rate of more than 40 % in graphene applications through 2030, with functionalized forms such as rGO-TEPA representing the fastest-growing segment (Grand View Research, 2024).

However, one of the persistent barriers to commercialization has been the lack of consistent supply and quality control at scale.

This is where Nanografi’s production capability fills a critical gap. By combining advanced synthesis control with rigorous quality assurance; covering amine-group density, purity, and batch reproducibility, Nanografi transforms rGO-TEPA from a laboratory specialty into an industry-ready raw material. This ensures that engineers, formulators, and researchers can transition from experimental results to reliable manufacturing without reformulation risk.

Conclusion

rGO‑TEPA exemplifies how controlled amine functionalization and precision reduction chemistry can elevate graphene beyond its conventional limits. It offers the rare combination of high electrical conductivity, enhanced chemical reactivity, and reproducible manufacturing stability that modern industries demand.

Its versatility—spanning energy systems, environmental technology, advanced composites, and smart electronics—positions it as one of the most adaptable materials in Nanografi’s advanced-materials portfolio.

Through the production and global distribution of high-purity rGO-TEPA, Nanografi empowers engineers, scientists, and innovators to turn research concepts into tangible, high-performance solutions. Each batch reflects a commitment to consistency, verified performance, and material integrity—so whether you are designing next-generation energy devices or lightweight conductive composites, Nanografi ensures your graphene performs exactly as engineered.

FAQ

Q1. What is rGO-TEPA?

It is reduced graphene oxide functionalized with tetraethylene pentamine (TEPA), introducing amine groups (–NH₂) that enhance interfacial bonding, dispersion stability, and electrical conductivity.

Q2. Why is TEPA functionalisation important?

TEPA adds reactive nitrogen functionalities that strengthen interfaces and enhance compatibility with diverse materials such as polymers, metals, and ionic species

Q3. In which industries is rGO-TEPA used?

It is widely applied in energy storage, composites, coatings, sensors, environmental remediation, and emerging areas like catalysis and 3D printing.

Q4. How does rGO-TEPA differ from standard rGO?

While rGO restores conductivity, rGO-TEPA also offers chemical reactivity through amine groups, providing better mechanical integration and stability.

Q5. Is industrial supply available?

Yes. Nanografi offers rGO-TEPA in both research and industrial grades, with certified specifications and consistent batch quality.

References

Alkhouzaam, A., et al. (2022). Spectral and structural properties of high-quality reduced graphene oxide produced via a simple approach using tetraethylenepentamine. Nanomaterials, 12(8), 1240. https://doi.org/10.3390/nano12081240

Han, Z., et al. (2015). Controllable synthesis of tetraethylenepentamine-modified graphene foam for the removal of lead ions. Scientific Reports, 5, 16744. https://www.ncbi.nlm.nih.gov/pmc/articles/PMC4652168/

Zhang, H., et al. (2022). Functionalization of graphene and its derivatives: progress and perspectives. Progress in Materials Science, 125, 100889. https://doi.org/10.1016/j.pmatsci.2021.100889

Gajula, P. (2024). Synergetic effects of amino-functionalized reduced graphene oxide (rGO-TEPA) and barium strontium titanate. Advanced Sustainable Systems. https://doi.org/10.1002/adsu.202300385

Rahdar, S. (2025). Functionalized graphene oxide for Cr(VI) removal: A systematic review of functional groups, mechanisms, and environmental applications. Separation and Purification Technology. https://doi.org/10.1016/j.seppur.2025.XXXX

Văduva, M., et al. (2023). Functionalization of graphene derivatives with conducting polymers and their applications in uric acid detection. Molecules, 28(1), 135. https://doi.org/10.3390/molecules28010135

Grand View Research. (2024). Graphene Market Size, Share & Trends Report 2030. https://www.grandviewresearch.com/industry-analysis/graphene-market

Recent Posts

-

Intelligent Porosity: MOF Engineering from Carbon Capture to the Quantum Frontier

Intoduction How far can the internal surface area of a material push the boundaries of its external …13th Feb 2026 -

Key Performance Metrics in Nanomaterials: How Performance Is Actually Evaluated

Introduction When nanomaterials are discussed, performance is often reduced isolated peak performanc …29th Jan 2026 -

Why Not All Graphene Is the Same: Structural Differences That Define Performance

Introduction Graphene is one of the most widely discussed materials in advanced technology, yet its …23rd Jan 2026