High-Tech Meets High Fashion: Conductive Inks for Smart Textiles

Fashion has always been an expression of identity, but now it has become a medium of interaction. Today, clothing not only reflects personal style - it senses, responds, and communicates. From temperature-regulating coats to light-reactive fabrics, technology is being woven into every fiber of modern design.

At the forefront of this transformation stands Nanografi Conductive Inks, engineering conductive formulations that enable textiles to transmit signals, store data, and respond to their surroundings. These advanced inks merge scientific precision with aesthetic innovation, allowing fabrics to perform intelligently while preserving comfort and design integrity.

The Rise of Wearable Intelligence

According to recent market data, the global wearable technology market is projected to surpass USD 200–220 billion by 2025, reflecting the rapid integration of smart materials and electronic systems across both consumer and industrial sectors (Mordor Intelligence, 2025; Grand View Research, 2025; IMARC Group, 2025). This milestone marks a new chapter in the convergence of fashion and technology — where functionality and design merge seamlessly.

Smart garments are no longer futuristic concepts; they have become data-driven tools that enhance performance and well-being. Sportswear now measures movement and heart rate, medical wearables monitor recovery, and defense uniforms automatically regulate body temperature or detect environmental changes.

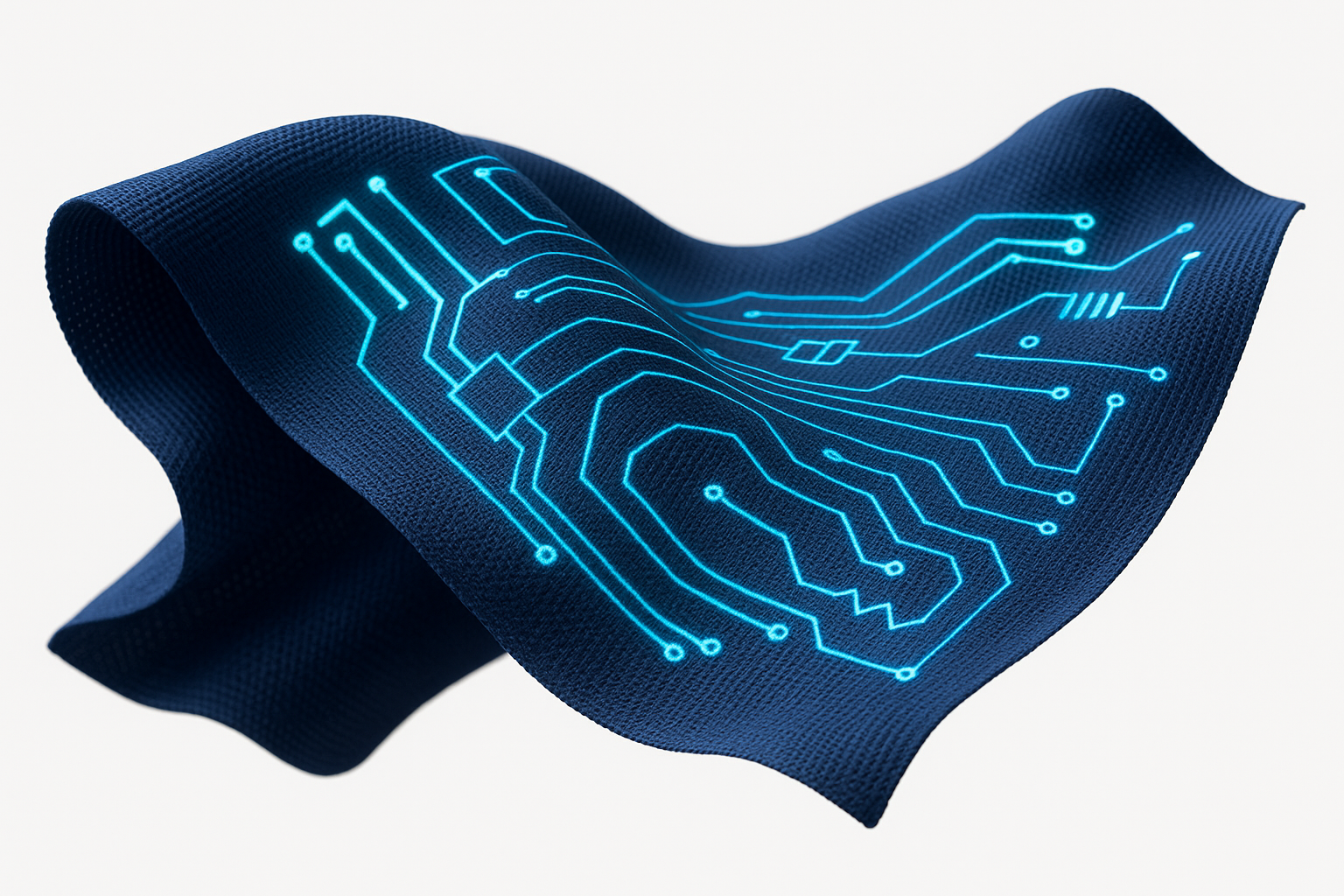

Conductive inks make these capabilities possible. As Khan, Lorenzelli, and Dahiya (2015) observe, printed electronic systems on flexible substrates form the foundation for wearable devices, enabling seamless integration between electronics and textiles.

Through the precision of conductive printing, Nanografi Conductive Inks transforms design surfaces into active layers - turning patterns into pathways and fabrics into functional systems.

Conductive Inks: The New Thread of Innovation

Conductive inks are specialized formulations composed composed of highly conductive silver or graphene-based nanoparticles suspended in printable matricessuspended in printable matrices. With appropriate formulation and processing, printed conductive traces can maintain functionality under bending and mild stretching.

This technology replaces traditional rigid circuits, providing lightweight, flexible, and eco-efficient alternatives for the next generation of wearables. Baysal (2024) reported formulations that retained functional conductivity after controlled laundering tests.

Nanografi’s graphene- and silver-based conductive ink portfolio offers high conductivity, strong adhesion, and low-temperature curing, making it suitable for textiles and flexible polymer substrates. These properties allow manufacturers to produce electronic fabrics using scalable methods such as screen printing and roll-to-roll processing.

Where Design Meets Science

The convergence of fashion and technology has given rise to an era where functionality enhances aesthetics. Today’s designers collaborate with engineers to develop intelligent textiles that are as expressive as they are practical.

Eghan (2025) highlights how hybrid materials - combining silver nanowires and carbon nanotubes - provide both flexibility and signal stability, unlocking new design possibilities. Conductive inks bring these materials to life through print precision, allowing circuit designs to follow the natural flow of a pattern, seam, or logo.

Within this intersection of art and engineering, Nanografi Conductive Inks ensures that every printed circuit is invisible to the eye but integral to performance. These inks transform creativity into connectivity, enabling textiles that look elegant yet operate intelligently.

Beyond Fashion: A Broader Spectrum of Use

The promise of conductive inks reaches far beyond haute couture. In healthcare, fabrics with printed sensors monitor patient recovery or wound conditions (Shah, 2022). In sports, activewear collects performance data without intrusive devices. In defense, soldiers wear uniforms embedded with circuits for communication or heat regulation.

Even consumer electronics, automotive interiors, and entertainment industries integrate conductive printing for flexible, interactive systems. In each case, Nanografi Conductive Inks empower a shift from rigid devices to responsive, lightweight, and design-driven technology.

Sustainability: Designing Responsibly

The rise of smart textiles aligns with an equally urgent global priority — sustainability. Conductive inks minimize electronic waste by replacing heavy components with printable, repairable, and recyclable circuits. Graphene and carbon-based systems reduce dependency on critical raw materials and lower manufacturing energy requirements.

Nanografi Conductive Inks divison integrates sustainability into innovation, developing eco-conscious formulations compatible with low-temperature, low-emission production. This approach supports major international initiatives such as the EU Green Deal and the UN Sustainable Development Goals, proving that intelligence and responsibility can coexist in material science.

Challenges and Future Directions

As the market grows, ensuring long-term performance under daily wear remains a key focus. Wash resistance, scalability, and uniform conductivity are among the main challenges. Yet progress continues rapidly.

Eghan (2025) notes that improved nanoparticle dispersion and encapsulation techniques are already addressing durability and reproducibility issues in e-textiles. Nanografi’s R&D division builds upon these findings, refining formulations that maintain both conductivity and flexibility over extended lifecycles.

As innovation continues, the distinction between fashion and technology will blur completely - giving rise to fabrics that are both expressive and intelligent.

Conclusion

Conductive inks are redefining how materials behave, enabling textiles to become platforms of communication, sensing, and interaction. They turn ordinary surfaces into dynamic systems, balancing scientific precision with design artistry.

Through its Conductive Inks division, Nanografi pioneers this integration of performance, beauty, and sustainability — helping industries craft intelligent fabrics that respond to the world around them.

FAQs

1. What are conductive inks?

Conductive inks are printable formulations with silver, copper, or graphene nanoparticles that create flexible electrical circuits on fabrics.

2. How do they support wearable technology?

They allow sensors and circuits to be printed directly onto flexible surfaces, making wearable systems lighter and more adaptable.

3. Are conductive inks washable?

Yes. Studies show that high-quality inks, such as Nanografi’s graphene- and silver-based types, maintain conductivity after washing and bending.

4. Where are conductive inks used?

In wearable sensors, medical garments, defense systems, and flexible electronic devices across multiple industries.

5. Are they sustainable?

Yes. Printable, recyclable circuits reduce waste and energy use, supporting EU Green Deal and UN sustainability goals.

6. What makes Nanografi’s inks different?

They combine high conductivity, flexibility, and environmental responsibility—engineered for real industrial use.

7. How big is the wearable tech market?

It’s projected to exceed USD 200–220 billion by 2025, driven by smart materials and electronic integration (Mordor Intelligence, 2025; Grand View Research, 2025; IMARC Group, 2025)

References

Baysal, G. (2024). Flexible and stretchable printable conductive inks for wearable textile applications. Tekstil ve Mühendis, 31(133), 49–62.

Eghan, B. (2025). Systematic review of conductive inks for e-textiles. Journal of Textile & Apparel Technology & Management, 16(2).

Khan, S., Lorenzelli, L., & Dahiya, R. S. (2015). Technologies for printing sensors and electronics over large flexible substrates: A review. IEEE Sensors Journal, 15(6), 3164–3185.

Shah, M. A. (2022). Applications of nanotechnology in smart textile industry. SN Applied Sciences, 4, 819.

Mordor Intelligence. (2025). Wearable Technology Market Size, Share, and Growth Trends (2020–2029).

Retrieved from https://www.mordorintelligence.com/industry-reports/wearable-technology-market

Grand View Research. (2025). Wearable Technology Market Size, Share & Trends Analysis Report By Product, By Application, By Region, And Segment Forecasts, 2024 – 2030.

Retrieved from https://www.grandviewresearch.com/press-release/global-wearable-technology-market

IMARC Group. (2025). Wearable Technology Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2033.

Retrieved from https://www.imarcgroup.com/wearable-technology-market

Recent Posts

-

Key Performance Metrics in Nanomaterials: How Performance Is Actually Evaluated

Introduction When nanomaterials are discussed, performance is often reduced isolated peak performanc …29th Jan 2026 -

Why Not All Graphene Is the Same: Structural Differences That Define Performance

Introduction Graphene is one of the most widely discussed materials in advanced technology, yet its …23rd Jan 2026 -

What Are Advanced Materials and Why They Matter for High-Tech Industries

Introduction Advanced materials are no longer peripheral inputs in technology development; they have …9th Jan 2026