How Security Inks Solved the Era of Document Fraud

From Hollywood forgeries to high-tech prevention

Remember Catch Me If You Can?

Frank Abagnale’s legendary escapades showed how a typewriter, a checkbook, and quick charm once fooled entire banking systems. Back then, the world relied on paper, pigment, and trust - and sometimes, the pigment gave way first.

Checks and legal documents were easy prey because:

- Paper stock lacked embedded fibers or security threads.

- Printing presses used widely available commercial inks.

- Colors and seals could be mimicked with a household copier.

Today, counterfeiting no longer happens at hotel rooms but on digital workstations with laser precision. The challenge is no longer to catch the fraudster - it is to make forgery scientifically impossible.

That is exactly what Nanografi’s security inks are designed to achieve. By merging nanotechnology, photophysics, and advanced materials science, we turn every printed document into a high-security surface capable of authenticating itself.

What makes an ink secure - layers of light and science

A secure ink is more than color; it is communication through light. Its optical behavior changes depending on how it’s viewed or illuminated — under ultraviolet or infrared light, it reveals patterns invisible to the naked eye.

Each formulation combines multiple defense layers that interact seamlessly:

- Overt features such as color-shifting or fluorescent effects for quick verification.

- Covert markers detectable only under UV/IR or magnetic inspection.

- Machine-readable signatures for automated validation.

This layered system ensures that any document - from a check to a notarized agreement or government license - carries visible confidence and invisible protection.

Inside the chemistry of modern anti-counterfeit inks

The science behind today’s security inks goes far beyond pigment and dye. It is a multidisciplinary field combining nanotechnology, polymer chemistry, photophysics, and surface engineering to create inks that behave like intelligent materials rather than simple colorants.

At the molecular level, security inks are designed to respond to external stimuli—light, heat, or even magnetic fields—by emitting, absorbing, or shifting light in a unique and measurable way. This reaction forms an optical “signature” that is nearly impossible to replicate without access to the exact formulation and nanoscale structure.

To achieve this, multiple chemical and structural innovations come together:

- Nanoparticle encapsulation: Active fluorescent or phosphorescent molecules are trapped inside polymer shells, protecting them from oxidation and ensuring stability under high temperature and humidity.

- Förster Resonance Energy Transfer (FRET): Pairs of light-sensitive molecules are positioned within nanometers of each other, creating fluorescence that occurs only when the exact nanoscale distance is maintained. Any deviation destroys the signal, making counterfeiting almost impossible.

- Rare-earth doping: Elements like europium (Eu²⁺) and neodymium (Nd³⁺) generate long-lived luminescence that remains bright even after years of circulation.

- Smart polymer matrices: These flexible, self-healing binders maintain optical consistency even after mechanical stress or abrasion.

Together, these systems turn an ordinary ink into a responsive security platform — a material capable of encoding complex optical data into a single printed line. Every drop carries its own built-in encryption, transforming simple color into a verifiable code of authenticity.

How multi-layer defense protects documents and value

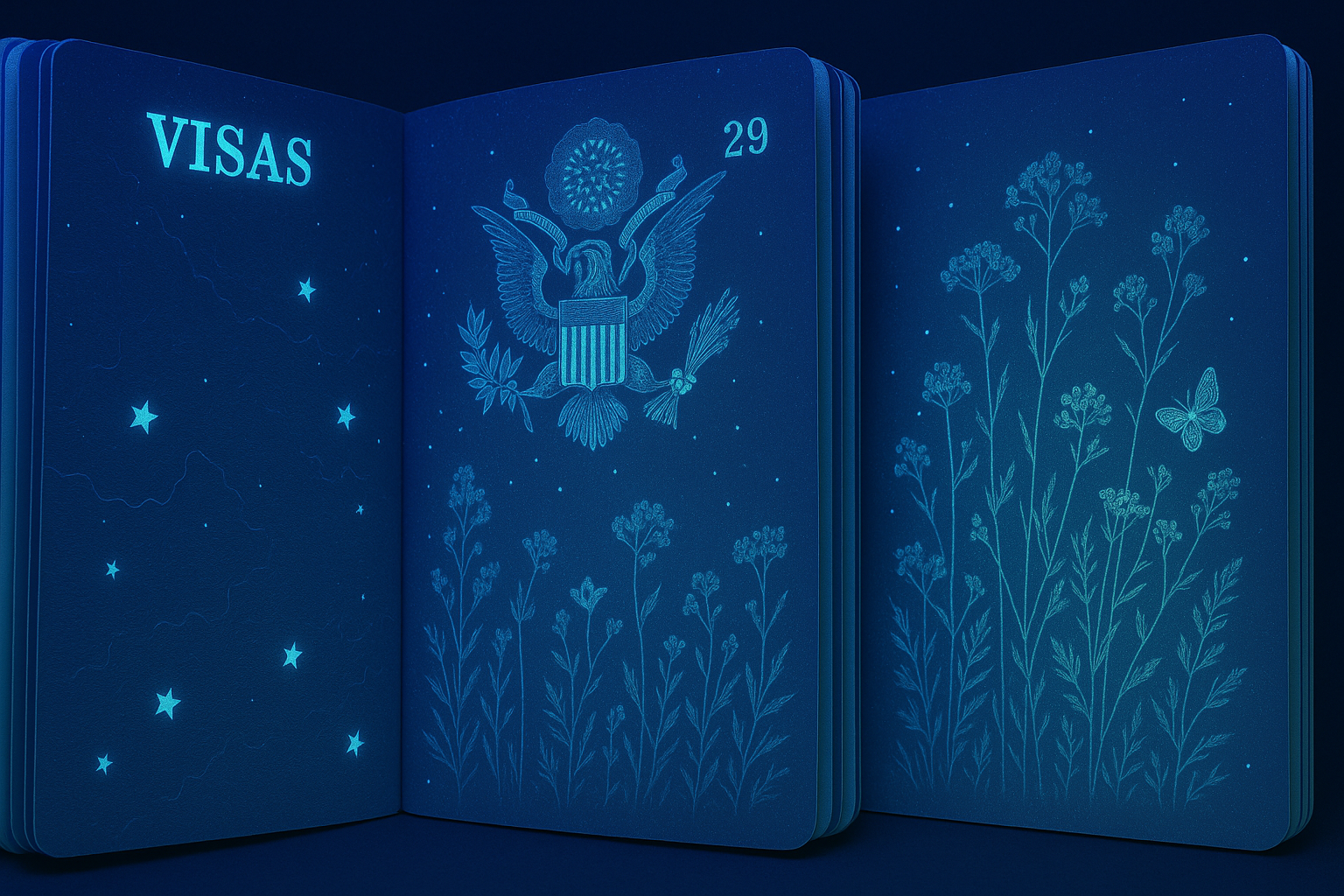

Security inks act as the first line of defense across multiple industries. Checks, passports, property deeds, educational diplomas, and identity documents all benefit from embedded optical safeguards.

For instance:

- Optically variable pigments change color as the document moves, deterring replication.

- Hidden UV or IR patterns verify authenticity instantly under inspection devices.

- Microscopic nano-structured textures make duplication nearly impossible.

- Chemical resilience prevents tampering through bleaching or solvent cleaning.

When combined, these features transform ordinary printing into an active verification system - one that protects institutions, governments, and citizens from forgery.

Beyond checks: Redefining trust in every document

Fraud no longer targets only financial instruments. Counterfeit business licenses, forged university degrees, and altered contracts all pose serious economic and reputational risks. Security inks add a quantifiable layer of trust to every official page.

Modern legal and administrative printing now integrates:

- Thermochromic labels that change color at touch or heat.

- Multi-spectral ink layers combining UV, IR, and visible responses.

- Traceable batch codes that connect each print to a verified source.

Studies from the Association of Certified Fraud Examiners (2023) confirm that such multi-featured protection can reduce document forgery attempts by up to 90 percent.

Sustainability and safety in ink formulation

Next-generation security inks are not only smarter — they are cleaner. The shift from metallic pigments and solvent-heavy carriers toward nano-engineered, water-based systems marks a decisive move toward greener chemistry.

Traditional anti-counterfeit inks often relied on heavy metals, halogenated solvents, and high-temperature curing processes. Today, advances in nanomaterial dispersion and polymer encapsulation allow similar or superior performance with fewer environmental drawbacks.

Modern production processes use water-based emulsions, low-energy curing, and precise additive dosing, minimizing chemical waste and energy use during synthesis. Many optical effects once achieved with toxic compounds can now be replicated through organic photoluminescent molecules or carbon-based nanostructures, significantly reducing the ecological footprint.

This new generation of inks represents more than an improvement in security — it signals a transition to a more sustainable era of advanced materials, where efficiency, durability, and environmental responsibility coexist in every formulation.

Conclusion — Chemistry, confidence, and catching up

Frank Abagnale once thrived in a world where ink was just color and paper carried trust. That era is over. Nanografi's Security inks now weave authenticity into the chemistry itself - turning light into a forensic signature that no imitation can reproduce.

At Nanografi, we continue to develop UV/IR-responsive, optically variable, and nano-tagged formulations that integrate smoothly into industrial printing processes worldwide. Whether protecting financial records, passports, or legal certificates, our inks redefine what it means to trust what you see.

Authenticity, once visible, is now verifiable - and that makes all the difference.

FAQ

Q1: Can security inks be used on any type of document?

Yes. Our formulations are designed for both paper and polymer-based substrates used in financial, governmental, and legal documents.

Q2: How long do UV or IR effects last?

Encapsulated pigments retain fluorescence for years under normal handling and light exposure, ensuring consistent detection through the document’s lifecycle.

Q3: Are Nanografi inks safe for the environment?

All formulations comply with international safety standards, using solvent-free systems and recyclable carriers to minimize ecological impact.

Q4: Can standard printers apply these inks?

Certain hybrid systems can, but optimal results require professional printing conditions that preserve spectral precision and durability.

References (APA)

Mardani, H., Bayrak, E., Özçelik, Ş., Babazadeh-Mamaqani, M., Kahveci, M. U., Roghani-Mamaqani, H., & Salami-Kalajahi, M. (2023). Anti-Counterfeiting Inks Based on Förster Resonance Energy Transfer in Microcrystalline Cellulose-Grafted Polyamidoamine for Artificial Industries. ACS Applied Polymer Materials, 5(2), 1092–1102.

Mardani, H. (2023). Anti-counterfeiting ink based on polymer nanoparticles containing spiropyran and Aza-BODIPY for artificial industries. Reactive and Functional Polymers, 187, 105593.

Wang, Z., Liu, Q., Wang, J., Qi, Y., Li, Z., Li, J., Zhang, Z., Wang, X., Li, C., & Wang, R. (2024). Luminescence performance and anti-counterfeiting application of Eu²⁺, Nd³⁺ co-doped SrAl₂O₄ phosphor. Nanomaterials, 14(15), 1265.

Association of Certified Fraud Examiners. (2023). Frank Abagnale Jr. and the Resurgence of Check Fraud. ACFE Industry Report.

Nanografi (2025). Where Security Meets Technology. Nanografi Inks Product Brochure.

Recent Posts

-

What Are Advanced Materials and Why They Matter for High-Tech Industries

Introduction Advanced materials are no longer peripheral inputs in technology development; they have …9th Jan 2026 -

Art That Changes Over Time: Stimuli-Responsive Materials Enabled by Nanotechnology

Art, design, and advanced materials are converging at an unprecedented pace, with nanotechnology in …19th Dec 2025 -

The Science Behind Super Suits: Advanced Nanomaterials, CNT Fibers and Graphene Composites

From Fiction to Advanced Nanomaterials in Real Protective Systems For years, popular culture has por …4th Dec 2025