Intelligent Porosity: MOF Engineering from Carbon Capture to the Quantum Frontier

Intoduction

How far can the internal surface area of a material push the boundaries of its external volume? With a free surface area capable of covering a football field in just a single gram and porosity reaching up to 90%, MOFs transform this question into the most radical answer in materials science. The awarding of the 2025 Nobel Prize in Chemistry to MOF architecture has confirmed that these structures are no longer mere laboratory 'objects of curiosity'; they have become strategic platforms that can be programmed with atomic precision for energy conversion, carbon management, and quantum technologies. At Nanografi, we define MOFs not just as traditional porous powders, but as 'smart molecular processors' engineered down to every detail, from pore geometry to surface defects to serve specific industrial purposes.

Structrual Modularity

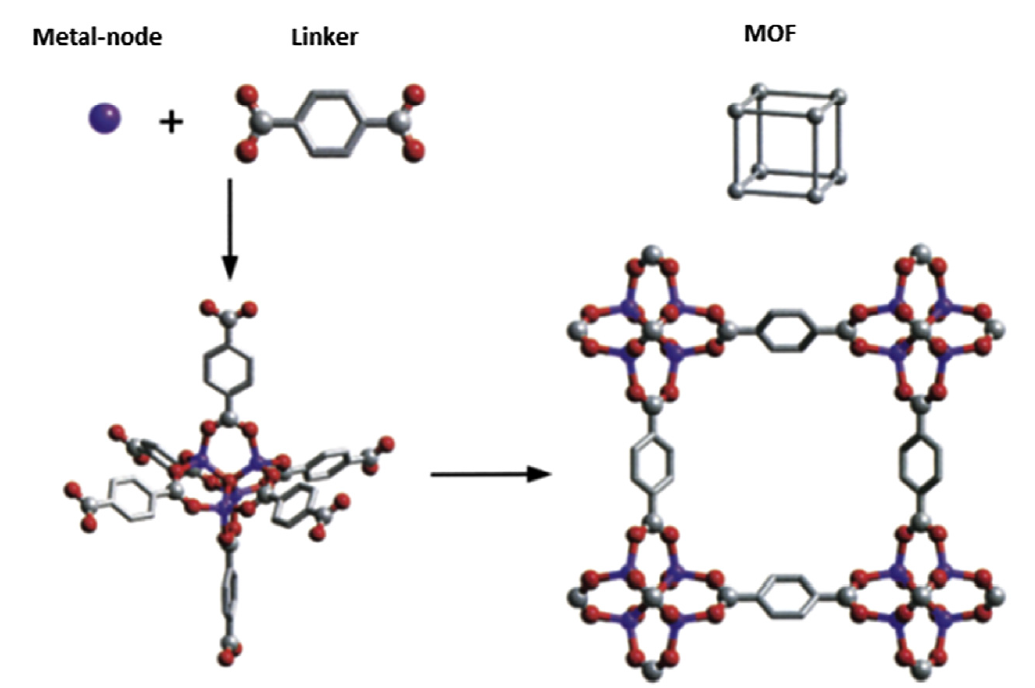

Metal-organic frameworks operate as integrated molecular architectures formed by the assembly of metal ions or metal-oxygen clusters (Secondary Building Units - SBUs) with organic linkers through coordination bonds (Fig. 1.). The most distinctive feature of these hybrid systems is their capacity to be atomically programmed, where the geometry of the metal node and the functionality of the organic linker govern the final performance outcomes with absolute precision.

Defined in the literature as "isoreticular chemistry," this design discipline allows for the quantifiable expansion of pore volume by modulating linker dimensions while maintaining strict network topology. This systematic expansion capability does more than just push the theoretical limits of surface area; it enables the kinetic optimization of diffusion rates, transforming the material into a site-specific engineered system for target gas molecules.

Figure 1. The structure of a MOF combined a metal node with an organic linker.

Kaynak: Bedia, J., Muelas-Ramos, V., Peñas-Garzón, M., Gómez-Avilés, A., Rodriguez, J. J., & Belver, C. (2020). Metal–organic frameworks for water purification. In Nanomaterials for the Detection and Removal of Wastewater Pollutants (pp. 241–283). Elsevier. https://doi.org/10.1016/b978-0-12-818489-9.00009-8

The Hidden Threshold of Performance: Activation Engineering

The most common misconception in the MOF community is reducing success merely to the theoretical surface area calculated in a laboratory environment. In reality, true industrial performance is defined not by synthesis quality alone, but by the discipline of activation, the removal of solvent molecules filling the pores after synthesis without damaging the crystal lattice.

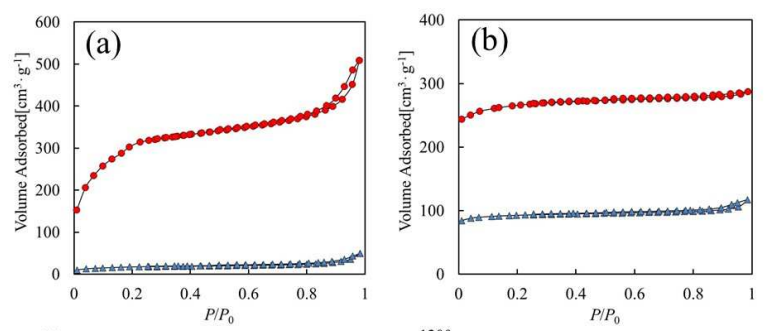

In structures with ultra-high surface areas, the surface tension and capillary forces generated during conventional drying often lead to pore collapse of the delicate framework. This structural failure highlights why theoretical metrics are insufficient for data-driven engineering decisions. A critical solution, especially for large-pore architectures, is supercritical CO2 activation, which evacuates the solvent without passing through the liquid phase, thereby preserving the structural integrity of the pores. As shown in Fig. 2., scCO₂ drying (red circles) preserves the framework integrity, allowing the materials to reach their maximum theoretical gas adsorption capacity compared to conventional drying (blue triangles). This rigorous process ensures that a true accessible surface area is obtained, capable of interacting with gas molecules under fully evacuated and stable operational conditions.

Figure 2. N2 adsorption/desorption isotherms for (a) MIL-53(Fe), (b) Cu3(BTC)2 prepared by scCO2 drying (red circle) and conventional drying (blue triangle).

Kaynak Matsuyama, K. (2018). Supercritical fluid processing for metal–organic frameworks, porous coordination polymers, and covalent organic frameworks. The Journal of Supercritical Fluids, 134, 197–203. https://doi.org/10.1016/j.supflu.2017.12.004

Stability and Defect Engineering

Stability remains the most critical barrier for the transition of MOFs from laboratory synthesis to high-fidelity industrial reactors. Structures such as zirconium-based UiO-66 stand out as gold standard materials due to their exceptional thermal and chemical resistance. However, Nanografi’s approach to modern engineering moves beyond passive stability; we enhance functionality by deliberately introducing missing-linker defect within these stable frameworks.

By strategically omitting certain linkers in a controlled manner, this approach can increase pore volume by up to 150%. The true revolution, however, is not merely structural expansion but the creation of coordinatively unsaturated metal sites (CUS), which are exposed at the node points as a result of linker removal. These open metal sites transform the MOF from a passive sponge into an active engineered platform capable of forming strong, selective chemical interactions with gas molecules. This transition from static porosity to active chemical sites is what defines the functional performance of a MOF in real-world operational conditions.

Application Roadmap: Engineering for Operational Environments

MOF technology establishes an application-specific balance between adsorption capacity, regeneration energy, and chemical stability. The true industrial value of these materials lies in the ability to optimize pore architecture according to the thermodynamic behavior of the target molecule. At Nanografi, we recognize that each application area requires a distinct engineering approach, where performance metrics must be evaluated relative to the target duty cycle and operational constraints.

In gas separation processes and carbon capture, MOFs operate with significantly lower regeneration energy compared to traditional amine solvents, offering a decisive advantage in energy efficiency. The commercial scale-up of structures like CALF-20 has proven that the material not only offers high capacity but also maintains its structural integrity even in moist flue gas streams—achieving a sophisticated balance between physisorption and chemisorption. In this context, the fundamental metric for success is the density and accessibility of active sites that provide the highest affinity for CO2 molecules under dynamic flux.

Performance in energy carriers, such as hydrogen and methane storage, faces divergent physical barriers depending on the temperature regime. While storage capacity correlates directly with total surface area under cryogenic (77 K) conditions, the key to success at room temperature is pore size engineering. Research indicates that the optimum pore size for hydrogen should be approximately ~6 Å; at this precise scale, the overlap of wall potentials maximizes the trapping of gas molecules at peak density. This transformation proves that a MOF is not merely a passive storage tank but a functional capsule that actively influences the physical state of the gas.

Furthermore, the transition to Tandem Catalysis demonstrates the MOF’s utility as an integrated "Microreactor." This approach manages multi-step chemical transformations within a single pore, significantly reducing industrial purification costs. For instance, in the production of 5-HMF from glucose, Lewis acid sites within the framework manage isomerization while added Brønsted acid groups simultaneously carry out dehydration. This "one-pot" strategy ensures that intermediate products are converted without leaving the system, maximizing yield and efficiency—a hallmark of high-fidelity material engineering.

Production Discipline: From Laboratory Synthesis to Plant-Scale Reliability

Industrial scale-up is a complex optimization process governed by mass and heat transfer constraints rather than a mere linear expansion of a laboratory synthesis recipe. In fast-crystallizing structures such as ZIF-8, modeling the nucleation and growth phases and monitoring them through in-situ tracking methods is essential for achieving the rigorous product consistency required by industry. At Nanografi, production is managed as a dynamic engineering operation where chemical evolution is kept under control at every critical stage of the reaction.

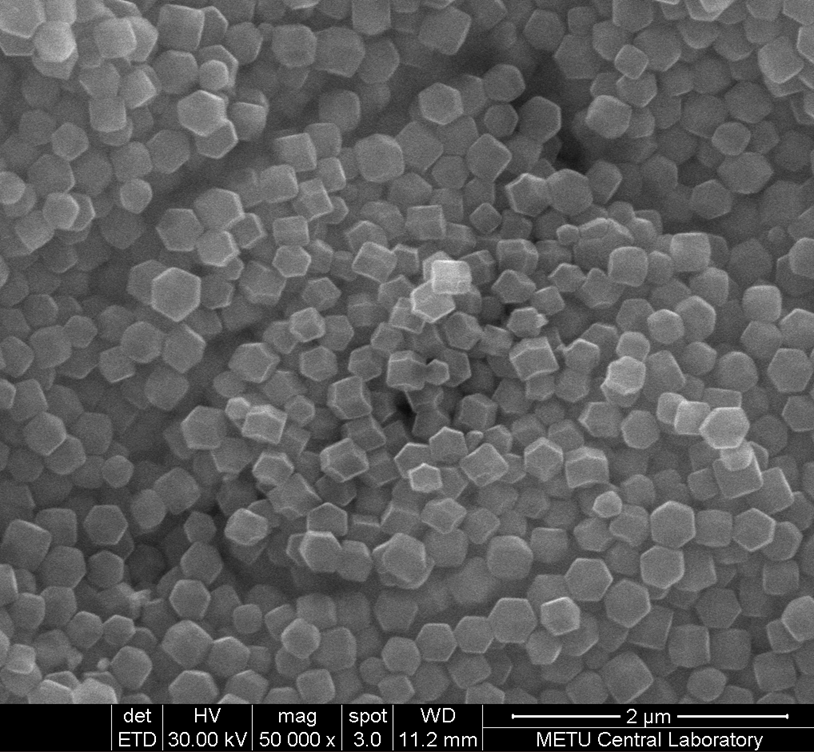

The success of the post-synthesis product is not defined by a single metric but through a holistic characterization backbone. Phase purity is confirmed via XRD, while pore distribution is validated through BET analysis. Furthermore, DLS and SEM morphology analyses are utilized to determine the pressure drop and diffusion characteristics essential for performance in industrial beds. This multi-variate validation ensures that the statistical process control and batch-to-batch reproducibility meet the highest standards, successfully transitioning laboratory-level performance into dependable plant-scale reliability. This multi-variate validation ensures that the statistical process control and batch-to-batch reproducibility meet the highest standards. As shown in our internal characterization data (Fig. 3-4), the sharp diffraction peaks in XRD and the uniform particle morphology observed in SEM confirm that Nanografi ZIF-8 achieves laboratory-grade precision at industrial scales. Thus, successfully transitioning laboratory-level performance into dependable plant-scale reliability.

Figure 3. XRD pattern of Nanografi ZIF-8.

Figure 4. SEM micrograph of Nanografi ZIF-8.

On the Frontier of the Future: AI Design and Quantum MOFs

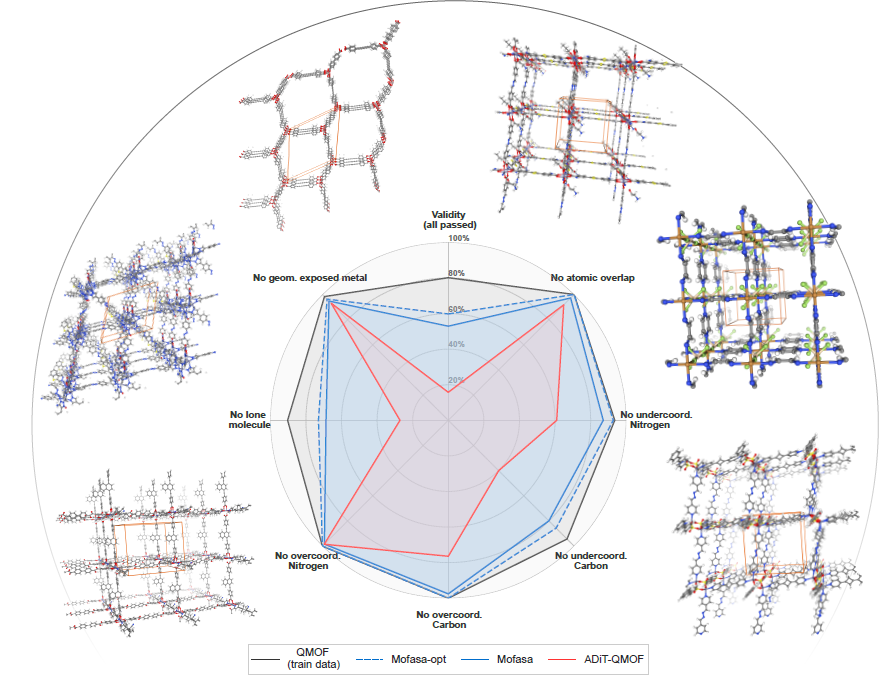

As the MOF landscape advances toward 2026, it is undergoing a profound transformation driven by two revolutionary waves that redefine material limits. The first wave is the development of digital twins for advanced materials through Generative AI. Latent diffusion models, such as "Mofasa," are accelerating "de-novo" structure discovery by conceptualizing millions of crystal systems from scratch. By bypassing the rigid building-block assumptions of the past, AI allows us to reach the "performance ceiling" of material design at unprecedented speeds. By bypassing the rigid building-block assumptions of the past, AI allows us to reach the ‘performance ceiling’ of material design at unprecedented speeds. As shown in Fig. 5, Mofasa achieves a 3.8× improvement in geometric validity compared to prior baselines, underscoring how generative AI is not only faster but also more reliable in advancing MOF design.”

Figure 5 . Geometric validation with MOFChecker. Mofasa achieves a 3.8× leap in reliability compared to prior baselines, marking a decisive step toward AI-driven performance ceilings in MOF design.

Kaynak: Šimkus, V., Christensen, A., Bennett, S., Johnson, I., Neumann, M., Gin, J., Godwin, J., & Rhodes, B. (2025). Mofasa: A step change in metal-organic framework generation (arXiv:2512.01756). arXiv. https://arxiv.org/abs/2512.01756

The second wave involves MOFs expanding beyond passive adsorption into active electronic and spin-based functionalities. In particular, altermagnetic spin-splitting observed in 2D planar structures—reaching levels as high as 83.9 meV—positions these materials as strategic candidates for future spintronic devices and quantum data processing. This "function programming" capability transforms MOFs from simple chemical aids into integrated engineered systems of the quantum era. At Nanografi, we view this evolution not just as a structural change, but as the ultimate alignment of material architecture with quantitative performance indicators for the next generation of technology.

Conclusion

Metal-Organic Frameworks have redefined the concept of static porosity offered by traditional materials like zeolites and activated carbon through molecular-level design (isoreticular chemistry) and controlled defect engineering. Today, MOFs have found their industrial counterparts as sorbents that enhance energy efficiency in carbon capture, storage units that push capacity limits with critical pore sizes for hydrogen, and microreactors that solve complex transformations in a "one-pot" manner during tandem catalysis. However, the true value-add of this material lies not just in record-breaking surface areas, but in the production discipline, ranging from activation quality to Avrami kinetics, that guarantees the same high performance in every batch.

As we enter 2026, MOF technology has reached the speed of "de-novo" design with Generative AI and stepped into the quantum realm through altermagnetic spin properties. By combining this scientific leap with scalable production and precise characterization standards, Nanografi continues to bridge the gap between laboratory efficiency and industrial reliability. Selecting the right MOF and optimizing its structure for process conditions is no longer just a material choice; it is the most strategic decision defining the performance ceiling of modern engineering systems.

References

Farha, O. K., Eryazici, I., Jeong, N. C., Hauser, B. G., Wilmer, C. E., Sarjeant, A. A., Snurr, R. Q., Nguyen, S. B. T., Yazaydın, A. Ö., & Hupp, J. T. (2012). Metal–organic framework materials with ultrahigh surface areas: Is the sky the limit? Journal of the American Chemical Society, 134(36), 15016–15021. https://doi.org/10.1021/ja3055639

Lara-Serrano, M., Morales-delaRosa, S., Campos-Martin, J. M., Abdelkader-Fernández, V. K., Cunha-Silva, L., & Balula, S. S. (2022). One-pot conversion of glucose into 5-hydroxymethylfurfural using MOFs and Brønsted-acid tandem catalysts. Advanced Sustainable Systems, 6, 2100444. https://doi.org/10.1002/adsu.202100444

Li, H., Eddaoudi, M., O’Keeffe, M., & Yaghi, O. M. (1999). Design and synthesis of an exceptionally stable and highly porous metal-organic framework. Nature, 402, 276–279. https://doi.org/10.1038/46248

López-Alcalá, D., Ruiz, A. M., Shumilin, A., & Baldoví, J. J. (2025). Chemical engineering of altermagnetism in two-dimensional metal-organic frameworks (arXiv:2512.14623). arXiv. https://arxiv.org/abs/2512.14623

Kuppler, R. J., Timmons, D. J., Fang, Q.-R., Li, J.-R., Makal, T. A., Young, M. D., Yuan, D., Zhao, D., Zhuang, W., & Zhou, H.-C. (2009). Potential applications of metal–organic frameworks. Coordination Chemistry Reviews, 253, 3042–3066. https://doi.org/10.1016/j.ccr.2009.05.019

Quan, Y., Parker, T. F., Hua, Y., Jeong, H.-K., & Wang, Q. (2023). Process elucidation and hazard analysis of the metal–organic framework scale-up synthesis: A case study of ZIF-8. Industrial & Engineering Chemistry Research, 62, 5035–5041. https://doi.org/10.1021/acs.iecr.2c04570

Rabe, T., Svensson Grape, E., Engesser, T. A., Inge, A. K., Ströh, J., Kohlmeyer-Yılmaz, G., Wahiduzzaman, M., Maurin, G., Sönnichsen, F. D., & Stock, N. (2021). Metal-dependent and selective crystallization of CAU-10 and MIL-53 frameworks through linker nitration. Chemistry—A European Journal, 27, 7696–7703. https://doi.org/10.1002/chem.202100373

Raptopoulou, C. P. (2021). Metal-organic frameworks: Synthetic methods and potential applications. Materials, 14(2), 310. https://doi.org/10.3390/ma14020310

Šimkus, V., Christensen, A., Bennett, S., Johnson, I., Neumann, M., Gin, J., Godwin, J., & Rhodes, B. (2025). Mofasa: A step change in metal-organic framework generation (arXiv:2512.01756). arXiv. https://arxiv.org/abs/2512.01756

Svante Technologies Inc. (2023, October 10). Svante secures commercial supply of MOF advanced sorbent materials with BASF for carbon capture market [Press release]. https://www.svanteinc.com/press-releases/svante-secures-commercial-supply-of-mof-advanced-sorbent-materials-with-basf-for-carbon-capture-market/

The Royal Swedish Academy of Sciences. (2025, October 8). Press release: Nobel Prize in Chemistry 2025 – Their molecular architecture contains rooms for chemistry [Press release]. NobelPrize.org. https://www.nobelprize.org/prizes/chemistry/2025/press-release/

Zhou, H.-C., Long, J. R., & Yaghi, O. M. (2012). Introduction to metal–organic frameworks. Chemical Reviews, 112(2), 673–674. https://doi.org/10.1021/cr300014x

Matsuyama, K. (2018). Supercritical fluid processing for metal–organic frameworks, porous coordination polymers, and covalent organic frameworks. The Journal of Supercritical Fluids, 134, 197–203. https://doi.org/10.1016/j.supflu.2017.12.004

Bedia, J., Muelas-Ramos, V., Peñas-Garzón, M., Gómez-Avilés, A., Rodriguez, J. J., & Belver, C. (2020). Metal–organic frameworks for water purification. In Nanomaterials for the Detection and Removal of Wastewater Pollutants (pp. 241–283). Elsevier. https://doi.org/10.1016/b978-0-12-818489-9.00009-8

Recent Posts

-

Intelligent Porosity: MOF Engineering from Carbon Capture to the Quantum Frontier

Intoduction How far can the internal surface area of a material push the boundaries of its external …13th Feb 2026 -

Key Performance Metrics in Nanomaterials: How Performance Is Actually Evaluated

Introduction When nanomaterials are discussed, performance is often reduced isolated peak performanc …29th Jan 2026 -

Why Not All Graphene Is the Same: Structural Differences That Define Performance

Introduction Graphene is one of the most widely discussed materials in advanced technology, yet its …23rd Jan 2026