The Science Behind Super Suits: Advanced Nanomaterials, CNT Fibers and Graphene Composites

From Fiction to Advanced Nanomaterials in Real Protective Systems

For years, popular culture has portrayed “super suits” capable of extreme impact resistance, thermal control, electromagnetic shielding, and seamless embedded electronics. While these cinematic armors belong to fictional universes, the underlying performance attributes increasingly align with what advanced nanomaterials can deliver today.

As Nanografi, we work at the core of this evolving materials ecosystem, delivering carbon nanotubes, graphene derivatives, MXene materials, and high-performance composites that accelerate the shift from fundamental research to industrial application.

Advances in carbon nanotube (CNT) fibers, graphene-reinforced polymer composites, and MXene-based EMI shielding films represent a major transition toward lightweight armor materials engineered for extreme environments. These next-generation materials -built on nanoscale mechanical, thermal, and electrical performance- form the scientific backbone of the protective platforms often depicted in science fiction.

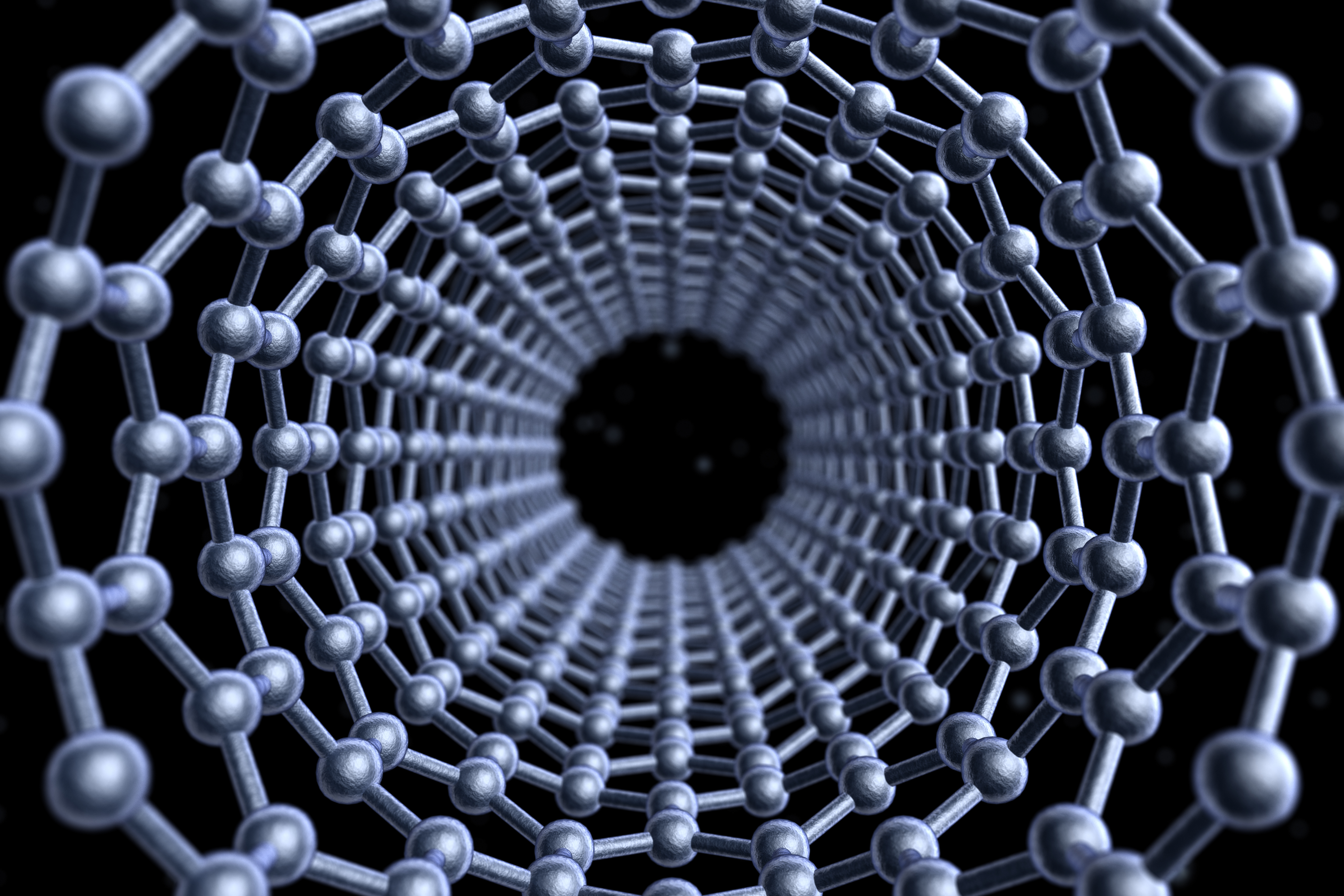

CNT Fibers and Carbon Nanotube Fiber Mechanical Properties in Lightweight Armor

Carbon nanotube fibers are among the strongest lightweight structural materials ever developed. Their nanoscale arrangement of continuous sp²-bonded carbon enables exceptional stress transfer, flexibility, and multifunctionality. Koziol et al. (2007) demonstrated that CNT fibers achieve tensile strengths exceeding 1 GPa while maintaining high thermal and electrical conductivity; properties rarely present simultaneously in structural systems.

These characteristics allow CNT fibers to address several long-standing challenges in armor design, especially for lightweight protective systems in defense and aerospace.

CNT Fiber Advantages

- Extremely high tensile strength and strength-to-weight ratio.

- Superior thermal conductivity, supporting thermal management materials in armor.

- Electrical pathways suitable for wearable sensor integration.

- Fatigue resistance exceeding traditional carbon fiber composites.

- Flexibility that enables articulated or textile-based protective layers.

At Nanografi, our CNT material portfolio -ranging from multi-walled CNTs to functionalized variants- supports engineers and research teams developing next-generation composites and protective systems that require both mechanical performance and multifunctionality.

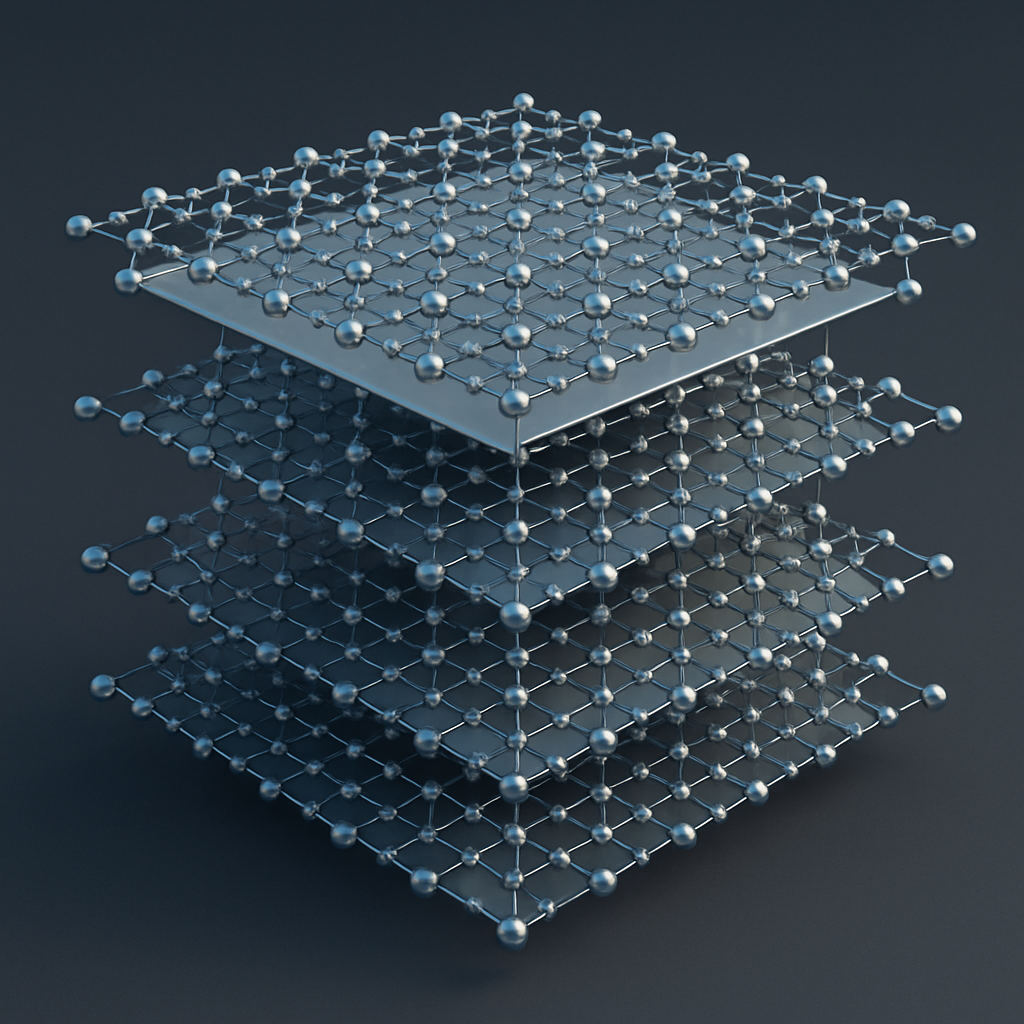

Graphene-Reinforced Polymer Composites for Impact Resistance and Thermal Stability

Graphene is another foundational material bridging the gap between fictional super suits and advanced protective systems. Its exceptional Young’s modulus (~1 TPa) and fracture strength enable polymer composites to deliver mechanical performance far beyond traditional carbon fiber-based laminates. Stankovich et al. (2006) showed that graphene-reinforced polymer composites significantly improve impact resistance, barrier performance, and thermal conductivity.

Engineering Benefits of Graphene Composites

- Expanded impact resistance through rapid stress distribution.

- High thermal conductivity, supporting heat dissipation in ballistic environments.

- Structural stability under mechanical load and environmental stress.

- Enhanced gas and chemical resistance for harsh conditions.

This combination makes graphene-enhanced materials ideal for ballistic protection, high-strain components, and thermal management applications.

Through our graphene oxide, reduced graphene oxide, and functionalized graphene products, Nanografi enables industries to integrate these nanoscale advantages into lightweight and high-strength composite architectures.

MXene Materials for EMI Shielding in Defense Applications

Many fictional super suits feature “energy shields,” cloaking systems, or advanced communication layers. In modern engineering, these correspond to electromagnetic interference (EMI) shielding - now essential for systems containing sensors, communication units, microprocessors, and distributed electronics.

MXenes represent one of the most advanced families of EMI shielding materials due to high electrical conductivity and tunable layered structures. Han et al. (2016) reported that Ti₃C₂ MXene films outperform many metallic foils in EMI shielding effectiveness while remaining lightweight and flexible.

MXene-Based EMI Shielding Capabilities

- Strong signal attenuation through conductive pathways.

- Interlayer polarization and multiple internal reflections.

- Lightweight structures outperforming metal foils.

- Textile compatibility for wearable protective equipment.

Nanografi’s MXene materials contribute directly to these emerging applications, supporting research and early-stage industrial adoption of high-performance EMI shielding layers used in defense, aerospace, and electronic protection systems.

Thermal Management Materials for High-Performance Protective Systems

Heat resistance -often depicted in fiction through fireproof or plasma-resistant armor- translates in real materials engineering to thermal conductivity, heat spreading, and thermal shock resilience. CNTs and graphene exhibit naturally high thermal conductivity, but hybrid composites with ceramic fillers (e.g., boron nitride, silicon carbide) deliver even higher stability.

These materials are essential for:

- Aerospace thermal shields

- High-velocity ballistic armor

- Wearable protective systems

- High-power electronic platforms

Nanografi’s portfolio of advanced thermal management materials supports these applications, enabling engineers to design protective systems with stable performance under extreme thermal loads.

Multifunctional Nanomaterials: Turning Armor Into an Integrated System

In fictional universes, super suits operate as intelligent platforms-sensing, responding, and communicating. Nanomaterials are driving this reality forward. CNT networks enable real-time structural monitoring; graphene electrodes support flexible energy storage; MXenes enable antennas, sensing layers, and tunable EMI behavior.

Integrated Capabilities Enabled by Nanomaterials

- Smart armor capable of detecting impact and strain.

- Physiological monitoring systems for aerospace and defense personnel.

- Flexible antennas and conductive pathways.

- Distributed, lightweight energy storage.

- Structural components with built-in sensing behavior.

As Nanografi, we work closely with research institutions, defense contractors, and technology companies developing multifunctional protective systems, supplying the advanced material platforms that enable these integrated capabilities.

Conclusion: The Road Toward Real-World Super Suit Technologies

Today’s engineered materials cannot yet deliver the self-healing, energy-field-based, or propulsion-augmented suits of fiction. However, the scientific foundation behind those concepts is rapidly emerging. CNT fibers provide unprecedented mechanical and multifunctional performance; graphene composites elevate thermal and impact capabilities; and MXene-based EMI shields deliver levels of signal protection previously achievable only with heavy metallic systems.

At Nanografi, our growing portfolio of CNTs, graphene materials, MXenes, and advanced composites empowers developers, researchers, and industry leaders working to transform these evolving material technologies into real-world protective platforms.

The boundary between science fiction and advanced engineered protection is no longer imagination-it is a measurable progression shaped by nanomaterials.

References

Han, M., Yin, X., Wu, H., Hou, Z., Song, C., Zhang, L., & Cheng, L. (2016). Flexible and conductive MXene films for high-performance electromagnetic interference shielding. Science Advances, 2(10), e1600842. https://doi.org/10.1126/sciadv.1600842

Koziol, K. K., Vilatela, J. J., Moisala, A., Motta, M., Cunniff, P., Sennett, M., & Windle, A. H. (2007). High-performance carbon nanotube fiber. Science, 318(5858), 1892–1895. https://doi.org/10.1126/science.1147635

Stankovich, S., Dikin, D. A., Dommett, G. H. B., Kohlhaas, K. M., Zimney, E. J., Stach, E. A., … Ruoff, R. S. (2006). Graphene-based composite materials. Nature, 442(7100), 282–286. https://doi.org/10.1038/nature04969

Recent Posts

-

Transistor - Effect MXene Membranes

Introduction Material science is undergoing a revolutionary transition from passive and static compo …27th Feb 2026 -

From Vibration to Information

Introduction Over the past decade, materials science has undergone a fundamental paradigm shift from …20th Feb 2026 -

Intelligent Porosity: MOF Engineering from Carbon Capture to the Quantum Frontier

Intoduction How far can the internal surface area of a material push the boundaries of its external …13th Feb 2026