Use of Nickel Materials in Battery Applications

Nickel, a versatile transition metal, has emerged as a key material in modern battery technologies due to its excellent storage capacity and higher energy density at a relatively lower cost. Its ability to resist high voltages and prevent overheating makes it an ideal choice for various battery applications, including electric vehicles, portable devices, and even satellites.

Nickel-based batteries, from the early Nickel-Cadmium (NiCd) to the latest Nickel-Rich Lithium-Ion batteries like NMC (Lithium Nickel Manganese Cobalt Oxide) and NCA (Lithium Nickel Cobalt Aluminum Oxide), have revolutionized the energy storage industry, providing long-lasting, efficient, and affordable power solutions. NiCd batteries are commonly used in portable devices, such as AA and AAA cells, while NCA batteries, which contain 80% nickel, and NMC batteries, with 33% nickel, are widely used in electric vehicles. This blog will explore the different types of nickel-based batteries, their advantages, and the important role nickel plays in shaping the future of energy storage. From anodes and cathodes to electrolytes and separators, Nanografi offes innovative solutions to improve battery performance and extend battery life. Visit Nanografi.

Introduction

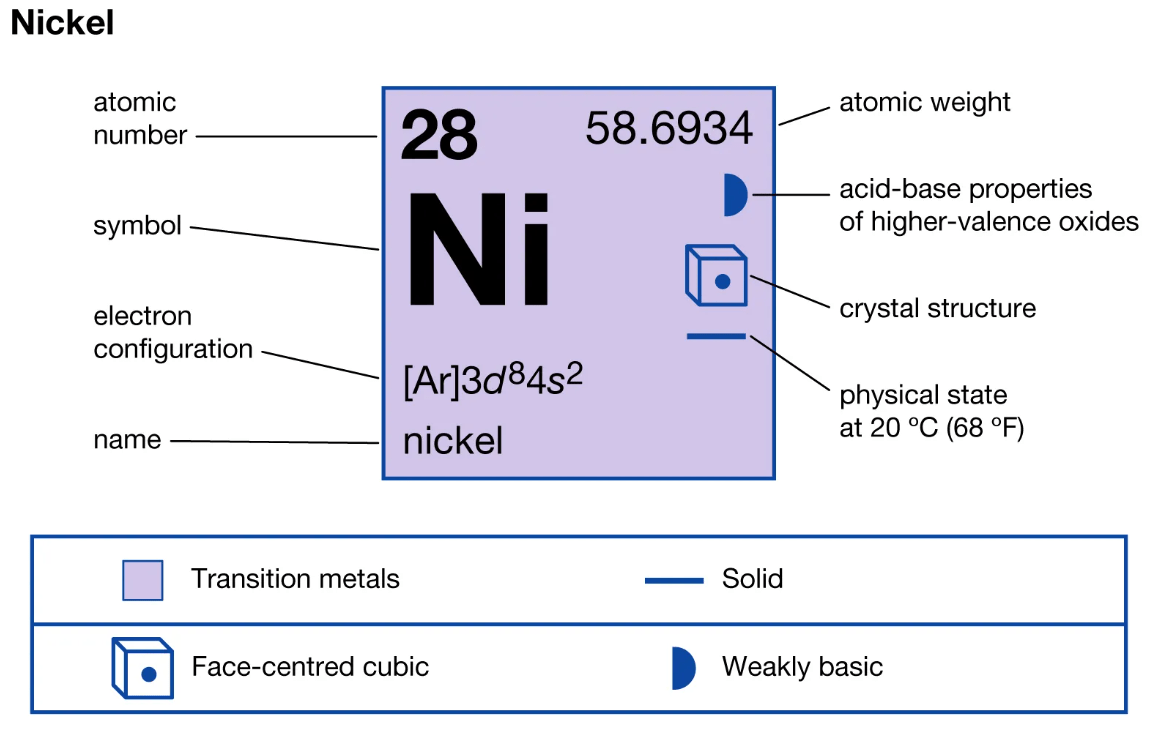

Nickel, with its atomic weight of 28 g/mole, has played a crucial role in the development of modern battery technology, offering high energy density and storage capacity at a relatively affordable price. Its ability to withstand high voltages and its conductive properties make it an essential component in various types of batteries, ranging from early Nickel-Cadmium (NiCd) batteries to the more advanced lithium-ion variations like NMC (Lithium Nickel Manganese Cobalt Oxide) and NCA (Lithium Nickel Cobalt Aluminum Oxide). These nickel-rich batteries are particularly significant in electric vehicle technology, where NCA batteries contain 80% nickel, and NMC batteries contain 33% nickel.

Overview of Nickel

Nickel is a relatively cheap metal and has higher specific energy thus it can deliver large storage capacity and high energy density at very low prices. Nickel is used as a cathode of multiple rechargeable batteries including lithium-ion batteries.

Nickel’s versatility has led to its use in a wide array of battery technologies, such as NiMH (Nickel Metal Hydride), NiFe (Nickel Iron), NiZn (Nickel Zinc), and NiH (Nickel Hydrogen) batteries. While NiCd batteries are commonly found in portable devices, the newer NCA and NMC lithium-ion batteries have become the backbone of electric vehicles and renewable energy storage systems. The durability and temperature resistance of nickel-based batteries make them reliable across various industries, from transportation to space applications. As we continue to innovate in energy storage, nickel remains a cornerstone of efficient, high-performance, and cost-effective battery solutions.

Properties of Nickel

Nickel is a silvery-white, ductile transition metal with excellent corrosion resistance, high melting and boiling points, and good electrical and thermal conductivity. Known for its ferromagnetic properties, nickel is commonly used in various industrial applications. Nickel's abundance, physical characteristics, conductivity, magnetic behavior, reactivity, and its role in alloy production and isotopic composition are outlined below:

Abundance of Nickel

Nickel is one of the most abundant metals in the Earth’s core, second only to iron. It has a concentration of approximately 80 ppm (parts per million), making it a key component in various industrial applications.

Color of Nickel

Nickel is a silvery-white solid metal, typically found in arsenic and sulfide ores. Its distinct color makes it recognizable and useful in many commercial and industrial products.

Melting and Freezing Point, and Density of Nickel

Nickel has a high melting point of 1455°C and a boiling point of 2730°C. Its density at room temperature is 8.908 g/cm³, making it a durable and resilient metal in high-temperature applications.

Physical Properties of Nickel

Nickel is known for its high malleability and ductility, allowing it to be shaped into wires, rods, sheets, and tubes without cracking. It is also relatively harder compared to iron, making it ideal for many industrial uses.

Conductivity and Magnetic Properties of Nickel

Nickel is a good conductor of both heat and electricity. It is ferromagnetic, meaning it exhibits magnetic behavior at room temperature. Nickel is one of the four metals that are naturally magnetic.

Reactivity of Nickel

Nickel is highly stable in its solid state and does not react with air. However, when finely ground and dispersed, it can ignite in air. Nickel’s resistance to rust and corrosion makes it valuable in many manufacturing processes.

Isotopes of Nickel

Nickel has several isotopes, including stable ones like 58Ni, 60Ni, 61Ni, 62Ni, and 64Ni, with 58Ni being the most abundant. Nickel alloys, such as stainless steel, nickel-chromium alloys, iron-nickel-chromium alloys, and copper-nickel alloys, are widely used for their diverse properties, including electrical resistance, shape memory, and magnetic behavior.

Figure 1. Properties of nickel in the element table.

Types of Nickel-Based Battery Technologies

Nickel-based battery technologies come in many types, offering high energy density, durability, and versatility, making them essential for powering everything from portable devices to electric vehicles and aerospace systems.

Nickel Cadmium Battery

These batteries make use of electrodes made using nickel oxide hydroxide, an alkaline electrolyte of potassium hydroxide, and metallic cadmium. These are rechargeable secondary batteries which are used for portable devices like camcorders, drills, computers and other small devices. This battery shows a memory effect though, i.e it can be rejuvenated and requires full discharges, periodically. It provides a voltage of 1.20V. This battery is banned in some countries due to Cadmiums’ toxic properties which make it hard to recycle.

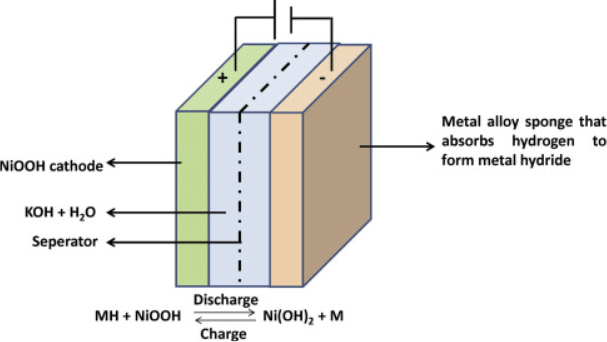

Nickel Metal Hydride Battery

These batteries have low internal resistance i.e. high self-discharge but can have a storage capacity of up to 2-3 times of same-sized NiCd, and an energy density approaching the one of a lithium-ion battery. Both Nickel Cadmium and Nickel Metal Hydride batteries use Nickel oxide hydroxide (NiOOH) as the cathode in their batteries and provide a voltage of 1.20V.

This battery is even harder to charge as compared to Nickel Cadmium considering that it self-discharges up to 20% in the first 24 hours after charging and about 10% every month after that. Thus NiMH’s rank is one of the highest in the class. Panasonic and Sanyo developed the Eneloop NiMH which was capable of storing charge for six times longer which meant a battery life of six-times the original NiMH battery, this innovation made the NiMH battery even more reliable.

Figure 2. Overview of Nickel Metal Hydride Battery.

Nickel Iron Battery

The nickel-iron battery is a rechargeable battery. It has an iron anode and a nickel oxide hydroxide cathode within a potassium hydroxide electrolyte. It produces a discharge of 1.20V. It performs well at high temperatures but fails at low temperatures. Per month, the battery has a high discharge of 20-40% and has a specific energy of about 50Wh/kg. This deemed Nickel Iron batteries unreliable. Although due to its long life its use is being considered again as its longer life requires less man-power required in recycling it. The properties of resistance to vibration and the ability to work in high-temperatures gave NiFe the chance to be used as the preferred battery in Europe, for mining. It was also used for the battery-powered V-2 rockets and the German V-1 flying bombs and during World War II.

Nickel Zinc Battery

This also uses Nickel oxide hydroxide as the cathode. It can be cycled about 200-300 times and has a specific energy of 100Wh/kg, which is relatively high. This battery is optimum for high power and high voltage uses. It is also available in AA sizes. Due to dendrite growth, the battery went through short cycle life and high self-discharge causing an electrical short in rail cars back in the 1930s and 1940s.

Nickel Hydrogen Battery

Encapsulated in a pressurized vessel, the cell includes solid hydrogen electrodes, nickel electrodes, electrolytes, and gas screens. It provides a voltage of 1.65V and has a long time before expiring. It has a good calendar life due to minimal self-discharge, low corrosion, and an amazing temperature range of –28°C to 54°C [2]. Due to such properties, this battery is ideal for LEO satellites.

NMC and NCA Lithium-Ion Batteries

A combination of nickel, manganese and/or aluminum are used in lithium-ion batteries to improve longevity, loading capabilities, and cost. In Lithium Nickel Manganese Cobalt Oxide (NMC), the cathode is a 1-1-1 ratio combination of cobalt, manganese, and nickel. NMC is the best choice for power tools, electric power trains, and e-bikes.

Use of Nickel in Battery Equipment

Nickel tabs

Nickel has many useful features which makes them one of the great and most frequently used materials for battery tabs. Nickel tabs are made from nickel alloy 201 which is ferromagnetic and has highly conducting properties and does not corrode easily. Lithium alloy is made with nickel due to its property to endure the highest voltage among metals such as Al and Cu which corrode at voltages lower than 4V while Ni can withstand up to 4.5V. It is easy to weld in comparison to other materials used in batteries. Due to its low resistance, it is very safe to use this material it does not heat up and waste energy or damage the battery.

Nickel foam for battery cathode substrate

Batteries are constructed keeping in mind that the internal resistance is low and the conductivity is high. Since porous materials are the most suitable to be used as current conductors for lithium-ion batteries nickel foam is used. It has low density since 75-95% space is void therefore it makes it the perfect material [3]. It is used in rechargeable batteries and is used as a current collector due to its properties such as high conductivity and three-dimensional structure.

Aluminum nickel composite strip for battery tab

Aluminum is used in lithium-ion batteries for battery tabs but since it does not have good welding properties nickel is used. Aluminum is plated with nickel, aluminum plating has many technical difficulties it has proven to be better than copper and tin. Aluminum and nickel have no plastic deformation so there isn’t a strong bond between the two materials that cause a large resistance in the cell. The layered composite tab is made from Nickel is 0.5 to 40% of the thickness of the positive electrode.

Nickel strip for battery tab

Pure Nickel strips are used in battery tabs since they can be easily weld and smoldered. Holes can be made into them to create extra bus bars by drilling into multiple strips at once or punching a hole at a time. The width of these strips determines their capacity to let varying currents pass through without corrosion. If the nickel strip is too thin it may easily corrode so to be on the safe side either nickel is use by layering it or soldering it or even using a copper wire. Nickel strips are widely used in electrical appliances, chemical machinery, rechargeable batteries, computers, cellular phones, power tools, and such other tools.

Other applications of nickel in battery equipment

Nickel is used in batteries, machinery, devices and numerous other appliances. Nickel has been used in Nickel Cadmium and Nickel Metal Hydrid secondary batteries over the past few decades. These batteries have proved to be long-lasting and rechargeable. From the smallest devices such as phones and cameras to cars and planes all use Ni batteries due to its low cost and high delivery. Besides batteries, there are many other valuable uses of nickel in various sectors.

Conclusion

Nickel has revolutionized batteries through its high specific energy properties, it is being used in electric cars, locomotives and other smaller devices, it is even being used in satellites. Nickel batteries come in all sizes and voltages. Although Nickel Cadmium battery has high toxicity levels Nickel Metal Hydride batteries provide a suitable alternative. Nickel batteries are highly popular and they are used in all types of appliances. Nickel batteries are constantly being improved upon and can be expected to bring technological advancement in the future.

To follow the latest developments and innovations related to nanotechnology, visit Blografi.

References

Coating Materials And Technology For Long Range Ir Coatings. (n.d.). Retrieved September 9, 2024, from https://www.materion.com/en/about-materion/news/coating-materials-news/coating-materials-and-technology-for-long-range-ir-coatings

Janghoon PARK | Principal Investigator | Doctor of Philosophy | Dupont, Delaware | Electronics & Industrial - HD MicroSystems | Research profile. (n.d.). Retrieved September 9, 2024, from https://www.researchgate.net/profile/Janghoon-Park-2

Nickel | Definition, Properties, Symbol, Uses, & Facts | Britannica. (n.d.). Retrieved September 10, 2024, from https://www.britannica.com/science/nickel-chemical-element

Nickel Metal Hydride Battery - an overview | ScienceDirect Topics. (n.d.). Retrieved September 10, 2024, from https://www.sciencedirect.com/topics/materials-science/nickel-metal-hydride-battery

NMC and Lithium Batteries: A Groundbreaking Relationship in Energy Storage - Nanografi - Nanografi Nano Technology. (n.d.). Retrieved September 10, 2024, from https://nanografi.com/blog/nmc-and-lithium-batteries-a-groundbreaking-relationship-in-energy-storage-nanografi/

The Future of Lithium-Ion Battery Applications - Nanografi Nano Technology. (n.d.). Retrieved September 10, 2024, from https://nanografi.com/blog/the-future-of-lithiumion-battery-applications/

Vasilyev, V. Y., Morozova, N. B., Basova, T. V, Igumenov, I. K., & Hassan, A. (2015). Chemical Vapour Deposition of Ir-based coatings: chemistry, processes and applications. J. Name, 00, 1–3. https://doi.org/10.1039/x0xx00000x

Recent Posts

-

An Overview of Laser-Induced Graphene: Methods, Properties, and Applications

A 3D porous substance known as laser-induced graphene (LIG) is developed by directly writing carbon …10th Jun 2025 -

Turning Noise into Power: Energy Harvesting with Piezoelectric Nanogenerators

Ambient acoustic energy, once an untapped resource, is now being converted into sustainable electric …5th Mar 2025 -

Holey Super Graphene in Li-ion Batteries: Next Generation of Energy Storage

Holey Super Graphene (hG), also referred to as “holey graphene,” is redefining li-ion ba …7th Feb 2025