Nickel (Ni) Micron Powder, Purity: 99.5+%, Size: 1-5 µm, Spherical

- SKU:

- NG01EM2604

- Shipping:

- Calculated at Checkout

Frequently bought together:

Description

25 grams/81 €

100 grams/231 €

500 grams/494 €

1000 grams/862 €

Please contact us for quotes on larger quantities !!!

Nickel (Ni) Micron Powder

Purity: 99.5+%, Size: 1-5 µm, Spherical

Technical Properties:

| Purity (%) | 99.5+% | |

| Particle Size (µm) | 1-5 | |

| CAS | 7440-02-0 | |

| Melting Point (°C) | 1453 | |

| Boiling Point (°C) | 2730 | |

| Density (g/cm³) | 8.908 | |

| Brinell Hardness | 75 Annealed | |

| Coeff. of Expansion @ 20°C |

13.3 x 10⁻⁶ | |

| Electric Resistivity (microhm-cm) | 6.844 microhm-cm | |

| Form | Powder | |

| Color | Gray | |

| Morphology | Spherical | |

| Elemental Analysis (%) | C | O |

| 0.5 max | 3 max |

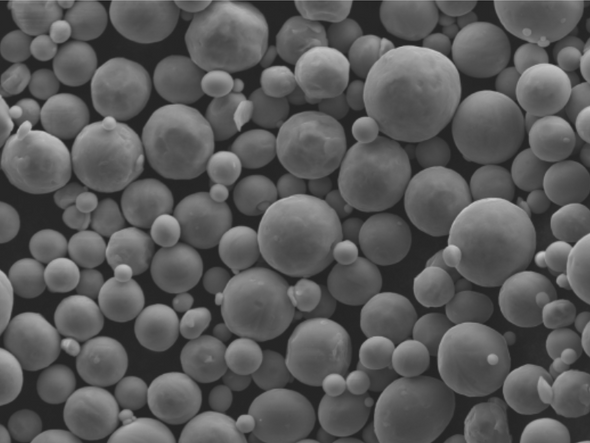

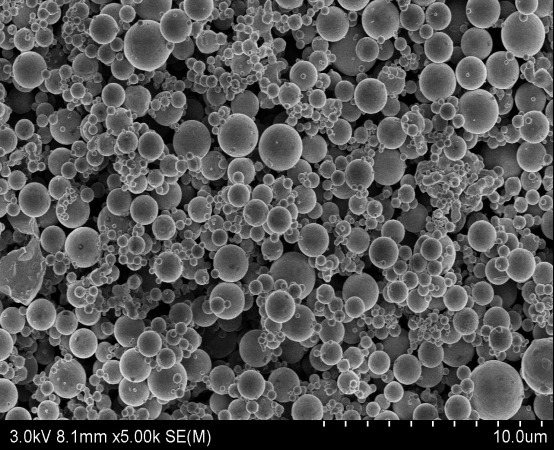

SEM Image:

Applications:

Its combination of 99.5 %+ purity, uniform spherical particles and excellent electrical/thermal conductivity makes it a highly adaptable filler across multiple industries. You can find a summary list below.

- Alloys & Metal Matrix Composites: Reinforces grain boundaries to boost mechanical strength and corrosion resistance in aerospace, automotive and structural alloys.

- Electronics & EMI Shielding: Improves flow and packing of conductive pastes, forming low-resistance, uniform networks for printed circuit boards, EMC coatings and shielding layers.

- Thermal Interface Materials: Enhances heat transfer in gap-filling greases and pads, increasing thermal management efficiency in CPUs, power modules and LEDs.

- Energy Storage: Acts as an electrode additive in lithium-ion batteries and supercapacitors, promoting fast charge/discharge rates and long cycle life.

- Additive Manufacturing: Serves as a feedstock for selective laser sintering and binder jetting, delivering controlled sintering kinetics, high density and consistent microstructure.

- Catalysis & Fuel Cells: Provides a high-surface-area support for heterogeneous catalysts and electrodes, improving activity and durability in hydrogen generation and fuel-cell reactions.

- Advanced Composites: Incorporated into polymer and ceramic matrices to enhance electrical conductivity, thermal stability and mechanical toughness for sensors, wearables and structural components.