Carbonyl Iron (Fe) Micron Powder, Purity: 97.5+%, Size: 1-5 µm, Spherical

- SKU:

- NG10MPW1529

- Shipping:

- Calculated at Checkout

NEW

Frequently bought together:

Description

25 grams/20 €

100 grams/45 €

500 grams/125 €

1000 grams/190 €

Contact us for tailored quotes on larger quantities & experience exceptional solutions from our experts.

Carbonyl Iron (Fe) Micron Powder

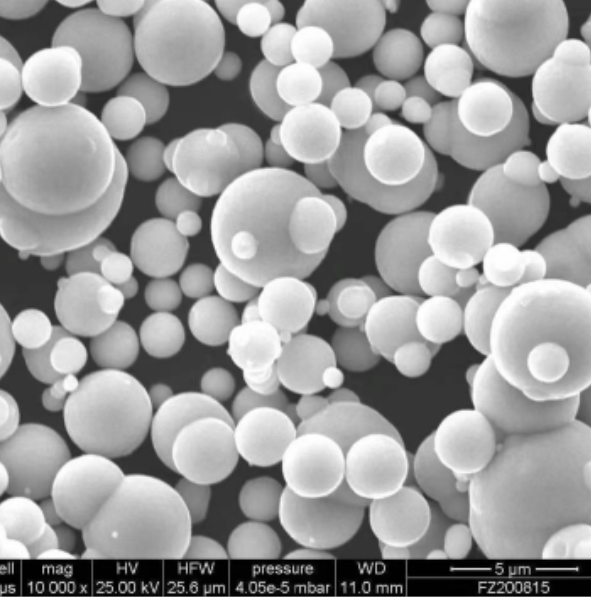

Purity: 97.5+%, Size: 1-5 µm, Spherical

Carbonyl iron micron powder is a spherical form of elemental iron produced by the thermal decomposition of iron pentacarbonyl. Its fine particle size distribution, high compressibility, and magnetic properties make it a versatile material for advanced manufacturing and functional applications. The spherical morphology ensures excellent flowability and uniform packing density, while its chemical purity supports both industrial and biomedical uses.

Technical Properties

|

Purity |

97.5+% |

|

Size |

1-5 µm |

|

Apparent Density |

2.0-3.0 g/cm3 |

| Morphology | Spherical |

| CAS No | 7439-89-6 |

SEM Image

Applications

- Powder Metallurgy: Used in precision components where high density and uniformity are required, enabling production of gears, automotive parts, and structural elements.

- Soft Magnetic Components: Incorporated into inductors, transformers, and magnetic cores due to its excellent magnetic permeability and low losses.

- Metal Injection Molding (MIM): Serves as a feedstock for complex-shaped metallic parts with high dimensional accuracy.

- Electromagnetic Interference (EMI) Shielding: Applied in coatings and composites to block or absorb electromagnetic radiation in electronics and communication devices.

- Magnetic Inks & Toners: Utilized in specialty printing applications requiring magnetic responsiveness.

- Pharmaceuticals & Nutrition: Recognized as a bioavailable iron source in dietary supplements and medical formulations, particularly for treating iron deficiency anemia.

- Research & Development: Employed in experimental magnetic materials, nanocomposites, and additive manufacturing studies.