Chromium Aluminum Boride (Cr2AlB2) MAB Phase Powder, Purity: 99+%, Size: 200 mesh

- SKU:

- NG10MPW1482

- Shipping:

- Calculated at Checkout

Description

5 grams: €140

25 grams: €375

100 grams: €1380

500 grams: €6370

1000 grams: €11940

Contact us for tailored quotes on larger quantities & experience exceptional solutions from our experts.

Chromium Aluminum Boride (Cr2AlB2) MAB Phase Powder

Purity: 99+%, Size: 200 mesh

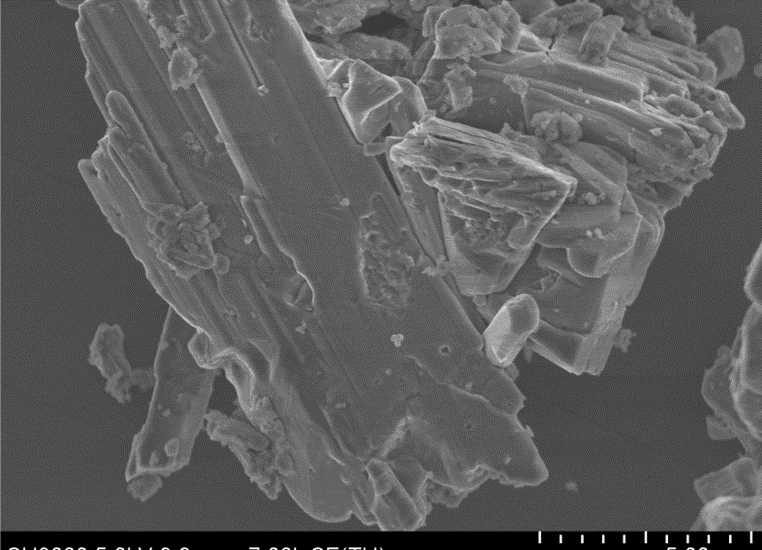

Chromium Aluminum Boride is a high-performance ternary boride belonging to the MAB phase family, characterized by an orthorhombic crystalline structure (Cmmm space group). Its micro-architecture consists of nanolaminated Cr-B layers interleaved with atomic sheets of aluminum, creating a material that exhibits the rigid mechanical strength of ceramics alongside the electronic properties of metals. From a materials engineering perspective, Cr2AlB2 is highly distinguished for its exceptional oxidation resistance at elevated temperatures; it possesses the unique ability to form a protective, self-healing alumina scale when exposed to air. This nanostructural configuration allows the material to resist brittle fracture through complex energy dissipation mechanisms, such as kinking and delamination, ensuring structural integrity in extreme thermal and mechanical environments.

Technical Properties

| Compound Formula | Cr2AlB2 |

| Purity | 99+% |

| Average Particle Size | 200 mesh |

| Appearance | Dark Gray |

SEM Image

XRD

Applications

- Advanced MABene Precursor Synthesis: Cr2AlB2 acts as the essential starting material for producing 2D chromium boride nanosheets, known as MABenes. These 2D derivatives are under intensive research for high-capacity energy storage, specialized sensing, and as conductive platforms for future nano-electronic devices.

- High-Precision Cutting & Abrasive Tools: Due to its inherent high hardness and wear resistance, the powder is used to manufacture or reinforce cutting tools. Its stability against thermal shock ensures that the tool's edge remains sharp and structurally sound even during high-speed machining where friction-induced heat is significant.

- Extreme-Environment Protective Coatings: Cr2AlB2 is utilized in thermal barrier and anti-corrosion coatings for critical aerospace and automotive components. The material's ability to form a dense, adherent oxide layer prevents environmental degradation and oxidation of underlying superalloys in jet engines and exhaust systems.

- Aerospace Propulsion Components: The synergy of ceramic-like thermal stability and metal-like conductivity makes it suitable for structural parts in aircraft and spacecraft. It is particularly valued for components exposed to high-velocity gas flows and rapid temperature fluctuations.

- High-Temperature Electrical Interconnects: Its metallic conductivity, coupled with resistance to oxidation, allows Cr2AlB2 to be used in electrical contacts and conductive ceramic substrates. These parts can operate reliably in oxidizing atmospheres where traditional metallic conductors would fail.

- Wear-Resistant Industrial Parts: In the mining and heavy manufacturing sectors, this material is used for components subject to intense abrasion. The robust Cr-B network within the lattice provides a durable surface that extends the service life of equipment operating in harsh, particulate-rich environments.