From Vibration to Information

Introduction

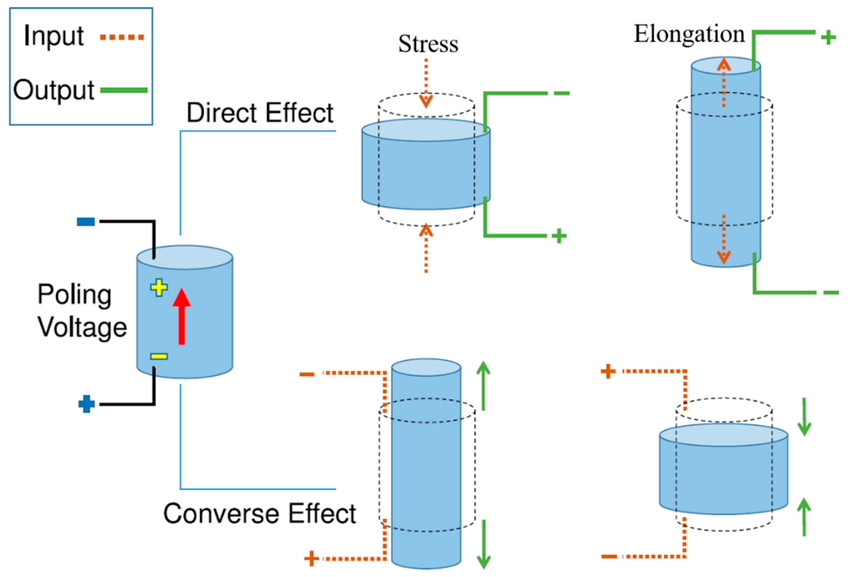

Over the past decade, materials science has undergone a fundamental paradigm shift from conventional static components to multifunctional systems capable of perceiving external stimuli and reporting their own structural condition. The most critical stage of this evolution is the ability of advanced composites, such as Carbon Fiber Reinforced Polymer (CFRP), to gain real-time data collection and transmission capabilities through nanomaterials integrated into their architecture—without compromising their structural load-bearing capacity. The cornerstone of this functionality is the piezoelectric phenomenon. The piezoelectric effect is the ability of materials with specific crystal lattice structures to generate electrical polarization under mechanical stress (direct effect) or exhibit mechanical deformation under an electric field (converse effect) (Fig. 1). From a materials engineering perspective, this bidirectional energy transduction allows the material to play an active role within the matrix as both a high-precision sensor and an energy harvester.

Figure 1. Direct and converse piezoelectric effect mechanisms (Atif et al., 2020).

Especially in critical components under dynamic loads, such as aerospace systems and wind turbine blades, although CFRP structures offer high specific strength, they are susceptible to micro-scale delaminations or matrix cracks developing in the internal layers. Traditional Structural Health Monitoring (SHM) methodologies rely on complex wiring networks added externally to the structure and external power sources with limited operational lifespans. These parasitic components reduce the system's total mass efficiency and limit long-term sustainability. The engineering approach presented by Sueda et al. (2026) overcomes these constraints by integrating piezoelectric nanomaterials directly as an interleaf between composite laminates. Thanks to this architecture, the material transforms into a smart structural platform that, without the need for an external power source, converts vibrations from the operating environment into energy to monitor its own structural integrity and autonomously report potential defects.

From Crystal to Electricity: The Piezoelectric Effect

At the center of this technological revolution, which is the cornerstone of modern materials science and smart systems, lies the piezoelectric effect—one of the most sophisticated physical mechanisms offered by nature. Etymologically rooted in the Greek word “piézein” (to squeeze/press), this phenomenon is the ability of materials with specific crystallographic symmetry to generate electrical polarization under applied mechanical stress (compression, tension, or torsion).

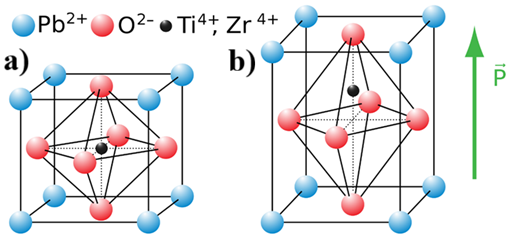

From a materials engineering perspective, this process is explained by the disruption of the non-centrosymmetric structure (lacking central symmetry) in the crystal lattice. Particularly in perovskite (ABO3) crystal structures, mechanical deformation leads to the displacement of ionic sub-lattices (Fig. 2). This microscopic displacement induces a net electrical dipole moment at the unit cell level, creating a high-precision voltage potential between the material's terminals on a macroscopic scale.

Figure 2. Microscopic mechanism of the piezoelectric phenomenon in ABO3-type perovskite crystal structure: (a) Symmetric and (b) asymmetric unit cell structure where electrical polarization is induced (Zhu et al., 2016).

A characteristic feature of this mechanism is its complete electromechanical reciprocity. While the direct piezoelectric effect converts a mechanical stimulus into digitizable data, the converse piezoelectric effect allows an applied electrical field to create predictable and controllable physical expansion/contraction within the crystal lattice. This synergistic nature positions piezoelectric materials as both ultra-precise transducers and flawless actuators controllable at the nanometric scale.

Today, this advanced engineering principle forms the nervous system of critical technologies; ranging from autonomous structural health monitoring systems used in aerospace to the tactile sense of surgical robots, and from high-frequency sonar systems mapping ocean depths to atomic-scale nanopositioning units required by the semiconductor industry.

The Legacy of PZT, The Vision of KNN

In the technological evolution of piezoelectric materials, Lead Zirconate Titanate (PZT) has been considered the industry's gold standard for decades, thanks to its high electromechanical conversion coefficients and wide operating temperature range. PZT's high d33 coefficient and excellent polarization stability have made it indispensable across a broad spectrum, from the most precise surgical instruments to the most demanding aerospace sensors. This material is the architect of the maturity level that piezoelectric technology has reached today, and the performance efficiency it offers continues to be a reference point for many applications.

On the other hand, the lead (Pb) content within PZT’s chemical composition, which exceeds 60% by mass, poses a significant engineering constraint within the framework of global environmental standards and sustainability protocols (such as RoHS). The toxicity of lead throughout its lifecycle, from production to disposal, has compelled researchers to migrate this superior performance onto an eco-friendly platform. The most robust and promising result of this pursuit is Potassium Sodium Niobate (KNN)-based nanomaterials.

With its biocompatible and eco-friendly character, KNN stands as the most strategic alternative to PZT, particularly in medical devices in contact with the human body and environmental energy harvesting systems. When synthesized in correct stoichiometric ratios and processed with precise chemical methods such as Sol-Gel, KNN-based nanocomposites can offer dielectric constants approaching the characteristic properties of PZT. This production methodology optimizes the homogeneous distribution of the nanomaterial within the polymer matrix, minimizing the risks of microscopic cracking in the film structure. As a result, KNN is carrying the baton inherited from PZT’s industrial legacy into the era of sustainable technology with its advanced dielectric constant (k) and high sensitivity values.

Invisible Sensors: Smart CFRP Architecture

The architectural design proposed by Sueda et al. (2026) offers a revolutionary hybrid structure in terms of materials science, based on the integration of KNN (Potassium Sodium Niobate) nanoparticles as an interleaf between Carbon Fiber Reinforced Polymer (CFRP) laminate layers. In traditional structural health monitoring strategies, external sensors are often regarded as parasitic elements, as they add extra mass to the structure and possess the potential to disrupt the mechanical continuity of the laminate. However, in this unique design, the piezoelectric layer becomes an intrinsic component of the matrix, contributing to the structural rigidity and providing functional depth without adding any additional weight to the system. The most remarkable engineering detail here is the dual-purpose use of carbon fiber layers: not only as a load-bearing skeleton but also as high-conductivity electrodes that transfer the charge generated across the piezoelectric layer.

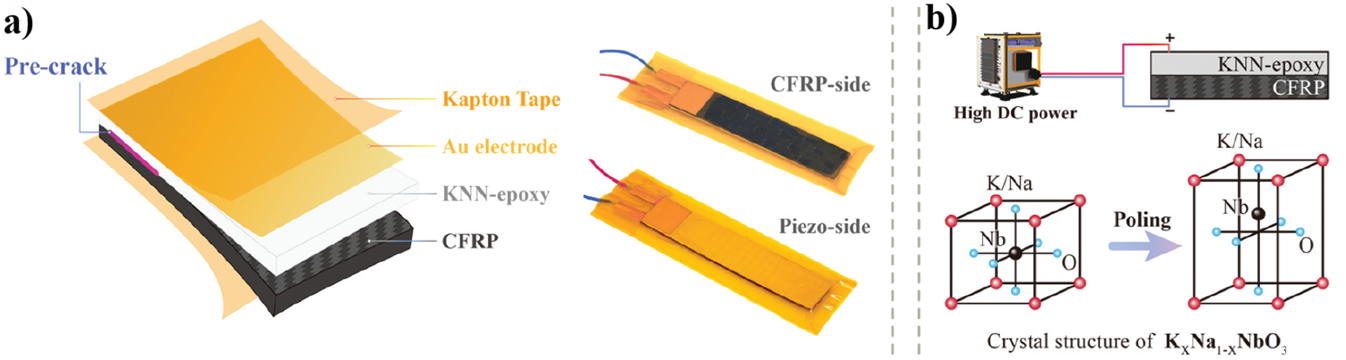

In this sophisticated hybrid configuration, KNN nanoparticles distributed within the epoxy resin matrix at an optimized volume fraction of 30% create a sensitive neural network that captures micro-scale vibrations experienced by an aircraft or a turbine blade. The polarization induced in the crystal lattice by mechanical deformation is collected via the carbon fiber electrodes and converted into an electrical signal within milliseconds. The physical appearance of the developed hybrid composite and the internal polarization mechanism that activates the material are presented in Figure 3.

Fig. 3. (a) Structural appearance of the KNN-epoxy reinforced CFRP composite and (b) the direct polarization process applied to induce electrical activity in the KNN crystal lattice (Sueda et al., 2026).

Advanced engineering analyses and experimental validation tests have revealed that this system can generate a peak voltage of 13.6 V from environmental vibrations—a value considered remarkably high for similar nanocomposites in the literature. This voltage level signifies more than just generating measurement data; it means the system can trigger low-power wireless data transmission modules (such as BLE or similar low-energy RF modules) without the need for external battery support. Consequently, this study merges energy harvesting technology with the discipline of smart sensing within a single structural body, taking the "self-powered sensor" concept from a laboratory prototype to the autonomous industrial standards required by critical sectors such as aerospace and energy.

From Passive Objects to Autonomous Organisms

The true technological superiority of the developed system lies in the sophisticated electromechanical correlation embedded within its structural defect detection methodology. Components under dynamic loads, such as aerospace fuselages or wind turbine blades, vibrate at a specific characteristic resonance frequency depending on their structural integrity and mass-rigidity distribution when in a healthy condition. However, when a micro-scale crack initiates within the composite matrix or inter-laminar separation (delamination) occurs, the structure's local stiffness matrix undergoes a fundamental change.

This microscopic physical alteration creates a direct change in the stress gradient across the integrated piezoelectric layer. The damaged area diverts the mechanical strain path experienced by the piezoelectric crystal lattices, leading to characteristic deviations in the voltage signal’s amplitude and frequency spectrum, identified as anomalies. Experimental studies conducted by Sueda et al. (2026) have proven an inverse correlation between crack propagation and voltage output. As the damage deepens and continuity is disrupted, piezoelectric efficiency decreases and the signal weakens. This implies that the material translates its own internal structural degradation into a digital attenuation signal.

This intelligent sensing capability is complemented by the wireless transmission of collected data via embedded micro-transmitters to a central artificial intelligence analysis unit. The result is a smart infrastructure ecosystem that goes beyond traditional maintenance processes requiring periodic and manual inspection—one that reports its own health 24/7 in real-time, predicts potential catastrophic failures while still at the micro-level, and dramatically reduces maintenance costs by minimizing operational downtime. With this technology, structures cease to be mere passive load-bearing objects and transform into autonomous organisms that proactively manage their own safety.

To find out more, you can read Carbon Nanofibers

Conclusion

This study proves that the integration of lead-free KNN nanoparticles into CFRP laminates is not merely an environmental necessity but a high-performance structural health monitoring solution. The value of the piezoelectric material here extends beyond being a passive filler; it serves as an active transducer that converts the mechanical energy experienced by the structure into actionable digital data. The peak voltage of 13.6 V obtained by Sueda et al. (2026) confirms that this advanced material possesses sufficient energy density to power low-energy data transmission modules (such as BLE) without the need for an external power source.

From a technical standpoint, the most critical output is the ability to correlate changes in mechanical rigidity directly with frequency deviations in the electrical signal, thanks to the sensitivity of the piezoelectric material. When this material success is combined with digital twin algorithms, damage detection will evolve from reactive inspections to a proactive, real-time monitoring system. Consequently, in sectors such as aerospace and wind energy, piezoelectric-based "fit-and-forget" sensor networks—which eliminate battery replacement costs and wiring weight—are now an industrial reality. Future studies focusing on the performance stability of these nanocomposites under long-term fatigue testing will accelerate the transition of this technology from the laboratory to the end-user.

References

Atif, R., Khaliq, J., Combrinck, M., Hassanin, A. H., Shehata, N., Elnabawy, E., & Shyha, I. (2020). Solution blow spinning of polyvinylidene fluoride based fibers for energy harvesting applications: A review. Polymers, 12(6), 1304. doi:10.3390/polym12061304 (figür 1)

Zhu, L., You, J. H., & Chen, J. First-principles calculations and molecular dynamics simulations on effect of hydrogen impurity in lead titanate films. Volume 9: Mechanics of Solids, Structures and Fluids; NDE, Diagnosis, and Prognosis. Presented at the ASME 2016 International Mechanical Engineering Congress and Exposition, Phoenix, Arizona, USA. 2016.

Sueda, Y., Wang, Z., Yu, Y., Watanabe, Y., Sato, H., Ohiwa, R., Shi, Y., Kurita, H., & Narita, F. (2026). From vibration to information: self-powered crack detection and wireless communication in carbon fiber reinforced piezoelectric nanocomposites. International Journal of Smart and Nano Materials, 17(1). https://doi.org/10.1080/19475411.2025.2610182

Wang, Z., Kurita, H., Nagaoka, H., & Narita, F. (2020). Potassium sodium niobate lead-free piezoelectric nanocomposite generators based on carbon-fiber-reinforced polymer electrodes for energy-harvesting structures. Composites Science and Technology, 199, 108331. https://doi.org/10.1016/j.compscitech.2020.108331

Yu, Y., Luo, C., Chiba, H., Shi, Y., & Narita, F. (2023). Energy harvesting and wireless communication by carbon fiber-reinforced polymer-enhanced piezoelectric nanocomposites. Nano Energy, 113, 108588. https://doi.org/10.1016/j.nanoen.2023.108588

Zhao, Z., He, L., Lin, Z., Wang, Z., Kurita, H., Shi, Y., & Narita, F. (2025). Self-powered multilayer impact sensor consisting of CFRP integrated with soft and hard piezoelectric layers. Composites Part B: Engineering, 304, 112683. https://doi.org/10.1016/j.compositesb.2025.112683

Tokay, O., & Yazıcı, M. (2022). A review of potassium sodium niobate and bismuth sodium titanate based lead free piezoceramics. Materials Today Communications, 31, 103358. https://doi.org/10.1016/j.mtcomm.2022.103358

Recent Posts

-

From Vibration to Information

Introduction Over the past decade, materials science has undergone a fundamental paradigm shift from …20th Feb 2026 -

Intelligent Porosity: MOF Engineering from Carbon Capture to the Quantum Frontier

Intoduction How far can the internal surface area of a material push the boundaries of its external …13th Feb 2026 -

Key Performance Metrics in Nanomaterials: How Performance Is Actually Evaluated

Introduction When nanomaterials are discussed, performance is often reduced isolated peak performanc …29th Jan 2026