Zirconium Hydride (ZrH2) Micron Powder, Purity: 99.5+%, Size: 1- 10 µm

- SKU:

- NG04CO2801

- Shipping:

- Calculated at Checkout

Frequently bought together:

Description

1 gram: 30 €

5 grams: 60 €

25 grams: 159 €

100 grams: 369 €

500 grams: 612 €

1000 grams: 935 €

Contact us for tailored quotes on larger quantities & experience exceptional solutions from our experts.

Zirconium Hydride (ZrH2) Micron Powder

Purity: 99.5+%, Thickness: 1-10 µm

Zirconium Hydride (ZrH₂) micron powder is a high‑purity (99.5+%) advanced material known for its excellent hydrogen storage capacity, thermal stability, and controlled reactivity, ZrH₂ is widely used in nuclear technology, metallurgy, and specialty alloy production. Its fine particle size ensures uniform dispersion and reliable performance in powder metallurgy processes. Zirconium Hydride also serves as a reducing agent, foaming agent, and precursor for advanced ceramics and hydrogen‑related applications. We supply ZrH₂ micron powder with consistent morphology and quality to support both research and industrial requirements.

Technical Properties

| Purity (%) | 99.5+ | |||

| Average Particle Size (µm) | 1-10 | |||

| Density (g/cm3) | 5,80 | |||

| Melting Point (°C) | 800 | |||

| Elemental Analysis (%) | Cl | Fe | Ca | Mg |

| 0.05 | 0.4 | 0.08 | 0.15 |

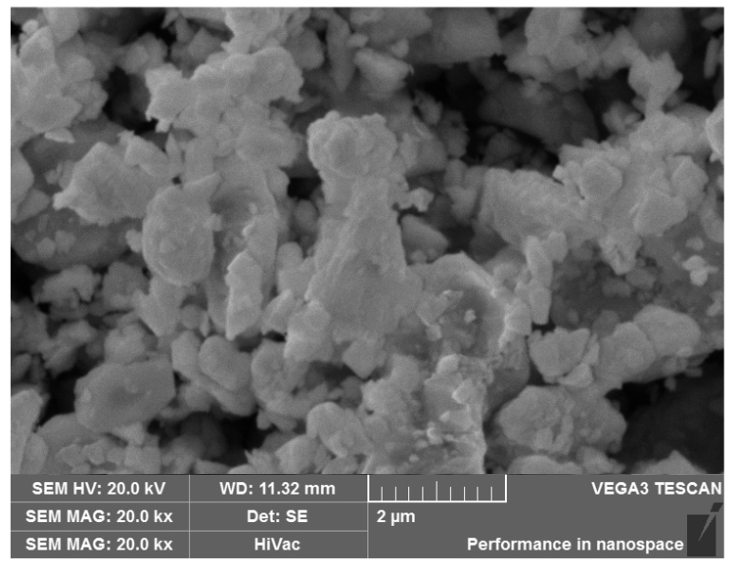

SEM Image

Applications

- Nuclear Technology: Zirconium Hydride is widely used as a neutron moderator and hydrogen storage material in nuclear reactors due to its stability and controlled reactivity.

- Metallurgy & Alloy Production: Serves as a hydrogen source and alloying additive in specialty metals, improving mechanical properties and processing efficiency.

- Powder Metallurgy: Fine particle size enables uniform dispersion, making ZrH₂ effective in sintering, foaming, and reducing agent applications.

- Energy Storage & Hydrogen Applications: Functions as a solid hydrogen carrier, precursor for hydrogen release systems, and material for advanced energy devices.

- Ceramics & Advanced Materials: Acts as a precursor in producing zirconium‑based ceramics and composites with tailored thermal and mechanical properties.

- Chemical Industry: Utilized as a reducing agent and foaming agent in various chemical processes requiring controlled hydrogen release.