Titanium Carbide (TiC) Nanopowder/Nanoparticles, Purity: 99%, Size: 35-55 nm

- SKU:

- NG04CO1902

- Shipping:

- Calculated at Checkout

Frequently bought together:

Description

5 grams/39 €

25 grams/62 €

100 grams/148 €

Please contact us for quotes on larger quantities !!!

Titanium Carbide (TiC) Nanopowder/Nanoparticles

Purity: 99%, Size: 35-55 nm

Technical Properties:

| Purity | 99% |

| Specific Surface Area (m2/g) | ≥20 |

| Morphology | Cubic |

| CAS No | 12070-08-5 |

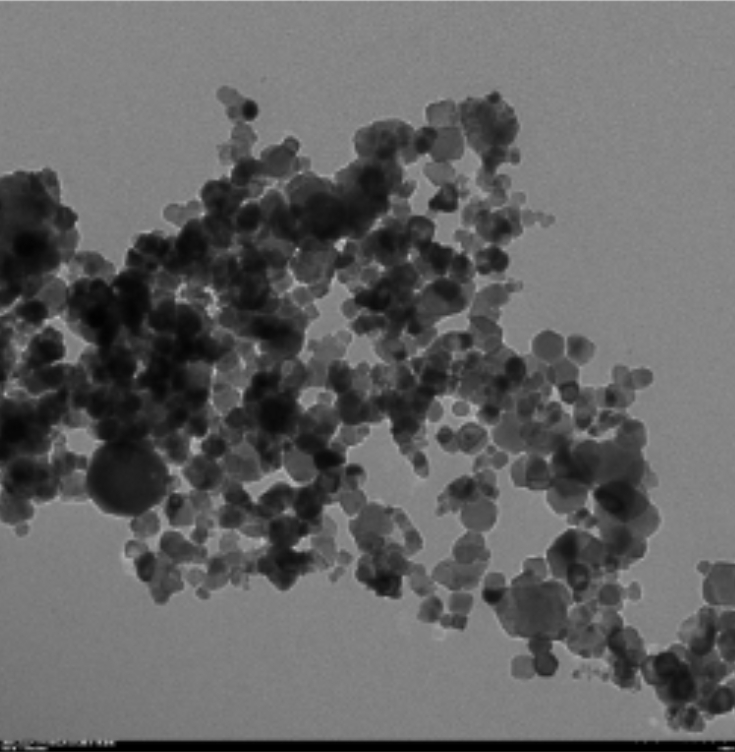

Tem Image:

Applications:

- Industrial Manufacturing: Titanium carbide nanopowder is widely used as a coating material to enhance wear resistance in cutting tools, nozzles, and steel bearings. Its high hardness and thermal stability make it ideal for extending tool life under abrasive and high-temperature conditions. When applied as a surface layer, TiC improves dimensional stability and reduces friction in precision components.

- Polymer and Composite Engineering: In polymer matrices, TiC nanoparticles serve as functional additives that improve mechanical strength, abrasion resistance, and electrical conductivity. They are compatible with various thermoset and thermoplastic resins, offering enhanced performance in structural composites and conductive plastics. Their fine dispersion contributes to uniform reinforcement and long-term durability.

- Electronics and Energy Systems: TiC nanopowder is used to boost conductivity in battery electrodes and EMI shielding materials. Its metallic-like behavior and thermal resilience support stable performance in high-power applications. It also contributes to the development of lightweight conductive polymers for flexible electronics and energy storage devices.

- Aerospace and Defense: Due to its extreme hardness and oxidation resistance, TiC is applied in aerospace-grade coatings for turbine blades, missile components, and lightweight armor systems. It enhances thermal barrier properties and protects surfaces exposed to high-speed particulate erosion. TiC-reinforced composites are also explored for structural parts requiring both strength and weight reduction.

- Medical and Biomedical Devices: Titanium carbide coatings are investigated for use in orthopedic implants and surgical tools where wear resistance and biocompatibility are critical. Its inert nature and mechanical robustness support long-term performance in load-bearing implants. Additionally, TiC’s micro-abrasive properties are utilized in dental polishing and precision cutting applications.