Multi Walled Carbon Nanotubes Isopropanol Dispersion, 10 wt%, Purity: >95%, OD: 30-80 nm, Length: <10 µm

- SKU:

- NG02CN0113

- Shipping:

- Calculated at Checkout

Description

15 ml/155 €

30 ml/270 €

60 ml/450 €

120 ml/765 €

Multi Walled Carbon Nanotubes Isopropanol Dispersion

Concentration: 10 wt%, Purity: >95%, OD: 30-80 nm, Length: <10 µm

MWCNT-Isopropanol (IPA) Dispersion (10 wt%) is a high-concentration, industrial-grade suspension designed for applications that require a significant carbon nanotube loading with a fast-evaporating carrier. Utilizing high-purity Multi-Walled Carbon Nanotubes (MWCNTs) with an outer diameter of 30-80 nm, this dispersion is engineered to provide excellent electrical and thermal conductivity within a variety of matrices. The Isopropanol medium ensures a low surface tension for superior wetting of substrates and a rapid drying time, which is essential for high-throughput manufacturing and spray-coating processes. This stable formulation eliminates the complexities of handling dry powders, offering a streamlined solution for integrating advanced nanomaterials into commercial products.

Technical Properties

| Purity | >95% | |

| MWCNT Content | 10 wt% | |

| Outer Diameter | 30-80 nm | |

| Inner Diameter | 5-15 nm | |

| Length | <10 µm | |

| Spesific Surface Area | >60 m2/g | |

| Tap Density | 0.18 g/cm3 | |

| CAS No | MWCNT | Isopropanol |

| 308068-56-6 | 67-63-0 |

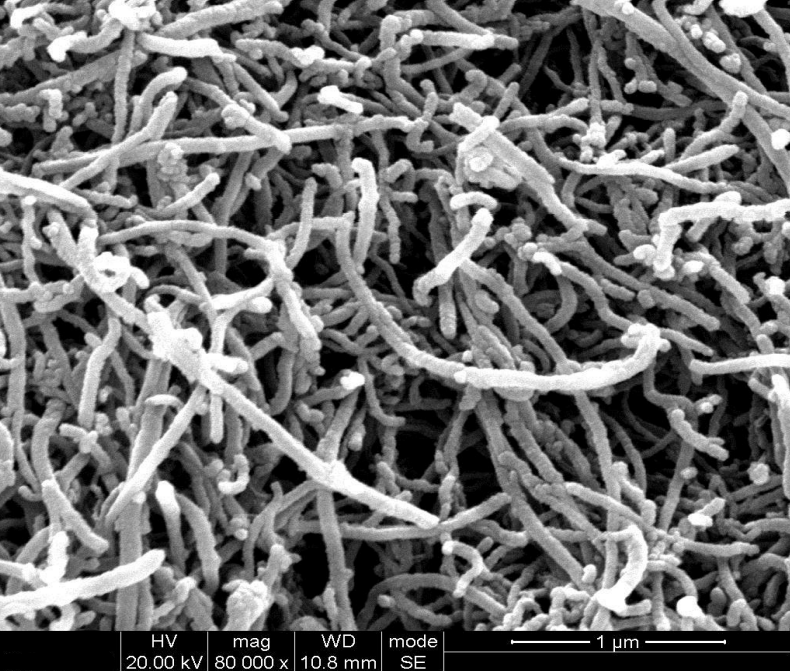

SEM Image

Applications

- Conductive Industrial Coatings: Development of fast-drying, anti-static (ESD), and conductive coatings for automotive parts, electronic housings, and industrial flooring.

- EMI/RFI Shielding: Formulating high-loading shielding paints and sprays that protect sensitive electronic equipment from electromagnetic interference.

- Advanced Polymer Composites: Serving as a concentrated masterbatch for alcohol-compatible resins and polymers to enhance mechanical strength and electrical properties.

- Energy Storage Electrodes: Used in research and production of battery and supercapacitor electrodes where an alcohol-based solvent is preferred for specific binder compatibility.

- Printed and Flexible Electronics: Creation of conductive inks for screen printing or spray-pyrolysis, enabling the fabrication of flexible circuits and sensors on various substrates.

- Anti-Corrosion Additives: Integration into protective coating systems to improve the barrier properties and durability of surfaces in harsh environments.