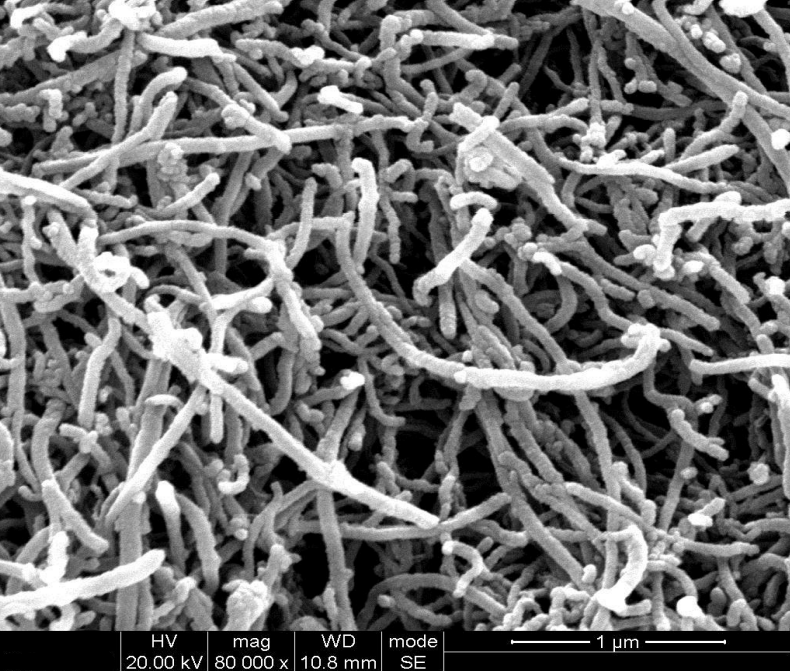

Multi Walled Carbon Nanotubes Water Dispersion, 10 wt%, Purity: >95%, OD: 30-80 nm, Length: <10 µm

- SKU:

- NG02CN0111

- Shipping:

- Calculated at Checkout

Description

15 ml/43 €

30 ml/65 €

60 ml/119 €

120 ml/179 €

Please contact us for quotes on larger quantities !!!

Multi Walled Carbon Nanotubes Water Dispersion

Concentration: 10 wt%, Purity: >95 %, OD: 30-80 nm, Length: <10 µm

MWCNT-Water Dispersion (10 wt%) is a high-purity, environmentally friendly suspension engineered for applications requiring high electrical and thermal conductivity without the use of harsh organic solvents. Featuring Multi-Walled Carbon Nanotubes with an outer diameter of 30-80 nm, this stable dispersion is optimized for seamless integration into aqueous-based systems. The water carrier makes it a safe and easy-to-handle solution for large-scale industrial use, significantly reducing Volatile Organic Compound (VOC) emissions. With its high concentration and uniform stability, it serves as a powerful additive to enhance the multifunctional properties of coatings, cementitious materials, and water-soluble polymers.

Technical Properties

| Purity | >95% | |

| MWCNT Content | 10 wt% | |

| Outer Diameter | 30-80 nm | |

| Inner Diameter | 5-15 nm | |

| Length | <10 µm | |

| Spesific Surface Area | >60 m2/g | |

| Tap Density | 0.18 g/cm3 | |

| CAS No | MWCNT | Water |

| 308068-56-6 | 7732-18-5 |

SEM Image

Applications

- Conductive Cement & Concrete: Integration into construction materials to provide "smart" capabilities, such as self-sensing (structural health monitoring) and enhanced mechanical durability.

- Water-Based Conductive Coatings: Development of eco-friendly anti-static (ESD) paints and decorative coatings for architectural or industrial electronics applications.

- Energy Storage Systems: Used in the fabrication of water-based battery electrode slurries (e.g., for certain Lithium-ion chemistries or flow batteries) to improve conductivity while meeting environmental regulations.

- Aqueous Polymer Nanocomposites: Reinforcing water-soluble or latex-based polymers to improve their tensile strength, thermal stability, and electrical performance.

- Textile & Fiber Modification: Application in the textile industry to create conductive or "e-textile" fibers through water-based dipping or coating processes.

- Paper and Packaging: Treatment of paper products to provide electromagnetic shielding or anti-static properties for specialized electronics packaging.